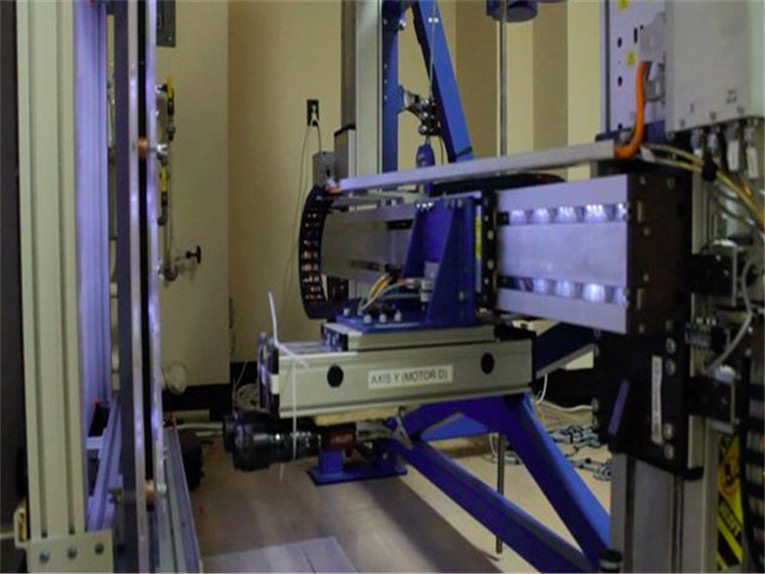

A Robotic Control XYZ Gantry

Machine-tool applications and the manufacture and assembly of semiconductor components account for more than half of all linear-motor use. That’s because linear motors are precise (albeit costly compared to other linear-motion options). Other applications for these relatively new motion components also include those that need fast and precise positioning or slow and extremely steady strokes.

Linear motor speeds range from a few inches to thousands of inches per second. The designs can deliver unlimited strokes and (with an encoder) accuracy to ±1 μm/100 mm. For this reason, a variety of medical, inspection and material-handling applications use linear motors to boost throughput.

Unlike rotary motors (which need mechanical rotary-to-linear devices to get straight moves) linear motors are direct drive. So, they avoid the gradual wear of traditional rack-and-pinion sets. Linear motors also avoid drawbacks of rotary motors running belts and pulleys … limited thrust because of tensile-strength limits; lengthy settling times; belt stretching, backlash and mechanical windup; and speed limits of 15 ft/sec or so. Plus linear motors avoid lead and ballscrew inefficiencies (about 50 and 90% respectively) as well as whip and vibration. They don’t force designers to sacrifice speed (with higher pitches) for lower resolution, either.

Multi-axis stages that use linear motors on each axis are more compact than traditional set-ups, so fit into smaller spaces. Their lower component count also boosts reliability. Here, the motors connect to regular drives, and (in servo operation) a motion controller closes the position loop.

Linear stepper motors deliver speeds to 70 in./sec, suitable for relatively quick-acting pick-and-place and inspection machines. Other applications include part-transfer stations. Some manufacturers sell twin linear steppers with a common forcer to form X-Y stages. These stages mount in any orientation and have high stiffness and flatness to a few nanometers for every hundred millimeters to output accurate moves.

Some cost-sensitive applications benefit from hybrid linear motors, as they have inexpensive ferromagnetic platens. Much like linear stepper motors, they vary magnetic saturation from the platen to shape opposition to magnetic flow. Feedback plus a PID loop with positioning control helps the motor output servo-grade performance. The only catch is that hybrid motors have limited output and exhibit cogging from coupling between forcer and platen. Two solutions are phase-teeth offset and driving for partial saturation of platen teeth and forcer teeth sections. Some hybrid motors also use external cooling to boost output during continuous operation.

Post time: Aug-13-2019