Metal components, Plastic components, Lubrication, Optional components and accessories.

For most recirculating ball and roller linear guides, the allowable operating temperature range is -10° to 80° C, with some configurations rated up to 100° C for brief periods. But not all applications fall within this temperature range, and each component in the linear bearing assembly (housing, rail, balls, seals, etc.) has a different maximum and minimum operating temperature. But if you choose the right metal components, plastic components, lubrication, and optional accessories, you can configure a recirculating linear guide that can withstand high (or low) temperature applications that fall outside the standard -10° to 80° C range.

Metal components

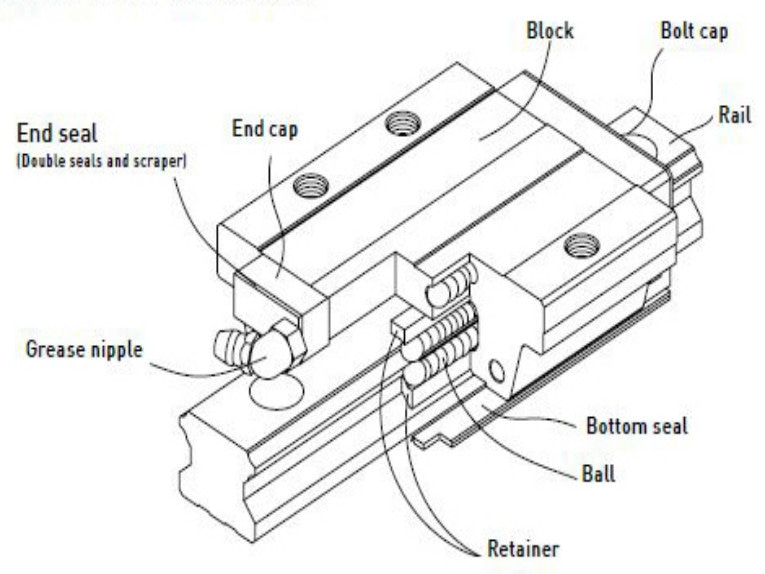

The metal parts of a recirculating linear guide include the bearing housing, recirculating balls or rollers, guide rail, scraper plates, and various fastening and mounting screws. The makeup of these parts can encompass three or more different types of steel, stainless steel, and — in some cases — aluminum. So it’s important to understand which type of metal each component is made of and what temperature range it can withstand.

In many cases, manufacturers recommend using stainless steels wherever possible when the application falls outside the normal operating temperature range, especially if the temperature is very high (above 150° C) or very low (below 0° C). One of the reasons for this recommendation is the possibility of temperature fluctuations, which can cause condensation and lead to corrosion.

Plastic components

Plastics parts, such as seals and recirculation components, are often a limiting factor in terms of the temperature suitability of a recirculating linear bearing. However, linear guide manufacturers offer seals made of special materials, such as FPM or FKM (fluorinated rubber, commonly known as Viton, from DuPont), with extended operating temperature ranges.

If the environment doesn’t present liquid or solid contamination, another option is to use a linear guide with only metal seals. And although forgoing seals altogether isn’t recommended for profiled linear guides (because they help to keep lubrication inside the bearing), round shaft linear guides and cam roller slides can be operated without seals, making them another option for applications that don’t call for the load capacity or rigidity of a profiled linear guide. And since these designs don’t require plastic recirculation components, they’re available in all-metal versions that can withstand temperatures outside the range of most plastics.

Lubrication

Temperature also affects the performance of lubrication in a recirculating linear guide. Specifically, the temperature of a lubricant affects its viscosity (resistance to flow), and grease lubrication that exceeds its rated temperature can separate into its components (base oil, thickener, and additives), reducing its effectiveness.

In general, lubricants with a lower viscosity are recommended for low-temperature applications, while higher viscosity lubricants are best for high-temperature applications. And keep in mind that in addition to the type of lubrication to use, the recommended lubrication interval is also affected by the operating temperature of the bearing.

Optional components and accessories

Temperature limitations also apply to optional components, such as additional seals, external lubrication units, and cover strips or bellows. For example, recirculating linear guides are typically rated for use at temperatures up to 80° C, but external lubrication units often have a maximum temperature rating of 50° to 60° C. Sensitive components such as measuring systems (integrated linear encoders) and parts that are integral to the recirculation system, such as ball chains or ball separators, should also be checked to ensure they can withstand excessively high or low operating temperatures.

Post time: Jan-18-2021