Machine automation is a very important part of industrial automation. Machine automation deals with processes that mean real production activities in a quick and accurate time; like bottle-filling machines, packing machines, labeling machines, etc. The processes which deal with the actual countability of products are called machine automation processes.

Motion control is thus an important part of machine automation because when you control motion, you directly control the movement of mechanical parts continuously. Control of mechanical parts results in the accurate production of the desired outputs. Motion control is majorly divided into two categories – linear and rotary.

What is Linear Motion?

As the name implies, linear motion is an activity in which a mechanical part moves in a straight line. For example, simply consider a cutting machine. Suppose you have chocolate cakes in your factory. In a production line, you want to regularly cut cakes for making smaller pieces. A cutter will continuously be controlled to cut in a vertical direction. This is linear motion.

Several other popular uses are linear motors, guides, bearings, and actuators. Let us have a look at the various types of actual products used in linear motion, which will help you understand the concept better.

Linear Motion Devices

An actuator is a pneumatically operated device, which when powered up by electricity, takes the inlet of air to push itself and do the task. When electricity is taken off, it cuts off the air inlet and pulls itself back to its original position. This is the most basic definition of an actuator.

Linear Actuator

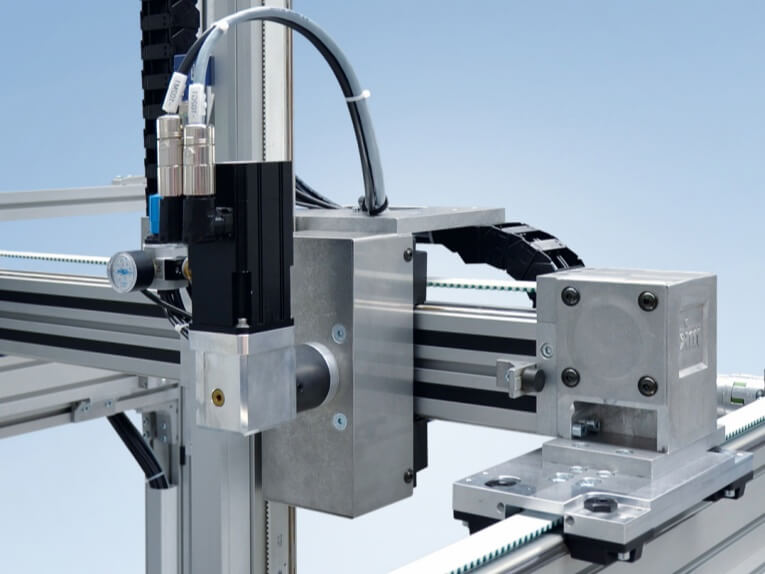

A linear actuator, as the name implies, will move in a straight line and do the required activity when triggered. When it comes to moving in a straight line, one thing to consider is the X-Y axis motion. The actuator can move either in an X-direction or a Y-direction. So, when designing and using a linear actuator, it is necessary to take into consideration this factor. Apart from these two, Z-direction also comes in a linear actuator.

When programming a linear actuator, you must know whether it needs to be moved in a single direction or multiple directions simultaneously. This is important to determine the mechanical ruggedness, reliability, and accuracy of the actuator. Linear actuators mostly move on a carriage or rail. So, this too needs to be considered depending on your application.

Ball Screw Actuators

Ball screw actuators work on mechanical screws through recirculating ball bearings. The screw moves on recirculation continuously, which helps it in rotating in a straight direction swiftly and efficiently.

The whole assembly travels on a threaded shaft and converts rotary motion into linear motion. They provide a high amount of torque and work on low friction. This reduces its downtime and also dissipates less amount of heat in its motion.

Belt Drive Actuators

Belt drive actuators are another innovation in linear motion technology. They work the same as a conveyor belt system, via a timing belt connected between two circular pulleys.

When you see a conveyor belt on how it moves linearly between two positions, this technology works the same on a belt drive actuator. The belt drive is enclosed within an aluminum body with the load-carrying carriage riding on top along rails.

Factors to be Considered in Linear Motion – Some of the important factors are discussed below.

Force

As discussed earlier, linear motion can move in either a single axis or multiple axes. The object can either carry a load or move freely to execute another task.

In any ways, force is a very important factor in choosing the right device. Based on the weight of the load (if present) or how fast it is needed to reach the destination, force plays a very important role here. Force can also help in determining how much friction it needs to undergo for executing that task.

Speed

Time plays a very important role in machine automation. Because you are producing something, if the production rate is slower, then there is no use for the machine. So, speed combined with force, shows how much power the device will need to operate with. If it is able to handle a good amount of weight, but in return it operates slowly, then it will hamper the production activities seriously.

Also, when speed is taken into the picture, two timings – acceleration time and deceleration time, need to be considered. If suppose it is required to decelerate quickly, then the said device must be able to quickly ramp down without any jerk or friction loss. The same goes for acceleration time.

Basically, it needs to be taken care that the device does not malfunction with any time set (though every machine has its limitation in the time set, it must at least perform properly in its given range.)

Stroke Length

When you are working with linear actuators, you must know how far they can travel. Every type of linear motion device has its own set of stroke lengths. The more the stroke length, the more you have the flexibility to play with the machine.

This is because you get a better reach of the end product and you can widely consider placing the machine at some distance; so that you get more area to place something else.

Duty Cycle

When you are continuously operating a linear motion device on and off, it too has some life for durability and ruggedness. How many times daily or yearly you can stroke the machine without any hiccups, determines the duty cycle. Basically, it is the frequency of operation for a machine.

Post time: Nov-27-2023