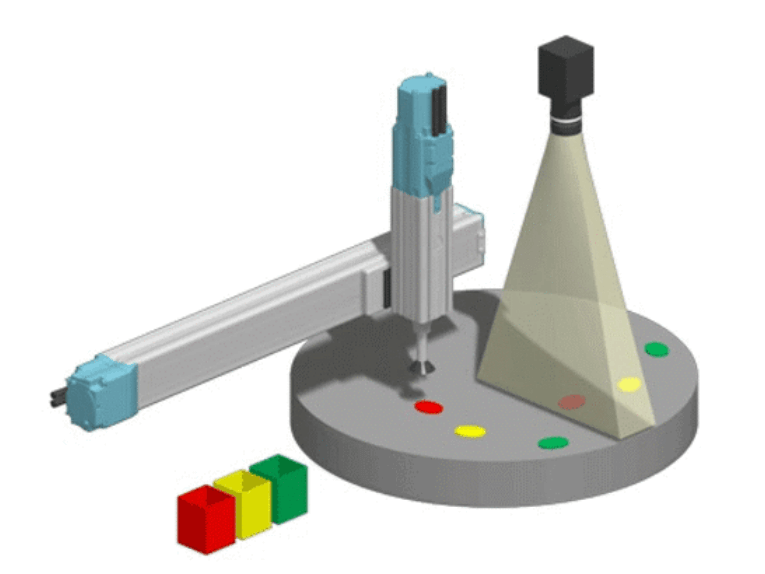

If you’re new to robotic automation, the idea of a Cartesian robot may seem like some tech-speak mumbo jumbo. But don’t worry, we’re here to demystify this concept, and help you understand whether a Cartesian robot is the right choice for your shop floor. A Cartesian robot is a mechanical arm that moves along three axes – X, Y, and Z in an orthogonal area. It gets its name from the Cartesian coordinate system that maps the robot’s movement patterns. Other names for Cartesian robots are Linear robots or Gantry robots. Let’s take a look at some common manufacturing applications for these robots:

- Pick-and-place, particularly in electronics assembly and packaging. Gantry robots can accurately choose, move, and place even minute components, making them ideal for assembling circuit boards, handling delicate parts, and performing other tasks that need an eagle eye.

- Material handling, such as loading and unloading CNC machines, transferring parts between stations, and packaging products. Cartesian robots can handle a variety of objects making them key assets in automated production lines.

- Assembly and inspection: Cartesian robots can perform a wide range of assembly tasks, including placing components, inserting fasteners, and applying adhesives. You can also use them for inspection tasks, such as scanning for flaws, which ensures higher standards, and verifies dimensional accuracy.

- Machine tending: these robots can effectively tend to CNC machines, loading and unloading workpieces, changing tools, and performing other tasks that would otherwise require human hands.

- 3D Printing: increasingly, we’re seeing the application of Cartesian robots to 3D printing. They provide precise control over the deposition of material. Also, their ability to move along three axes allows them to create complex three-dimensional objects.

But that’s not all. Many manufacturers are increasingly using Cartesian robots for a variety of other processes, such as welding and painting, making them well-established assets in many industrial settings, such as the automotive industry. Another point worth noting is that Cartesian robots are not fully articulated arms. Thus they may be limited in their range, reach, or versatility when compared to newer models.

Benefits of using a Cartesian robot

Why are Cartesian robots so great for automation, then? Here are a few reasons:

- Precision and accuracy: They excel at high-precision tasks that need extreme accuracy, like assembling electronic components or loading and unloading workpieces.

- Low maintenance: They have a simple mechanical design with few moving parts, so they’re low-maintenance, durable, and less prone to pesky breakdowns.

- Flexibility: You can reprogram them for different tasks, as well as swap in different end-effectors or tools.

- Cost-effective: They’re often cheaper to implement than other robot types, hovering between $5000 to $15000. Also, they don’t require an engineering degree to program, so they’re comparatively easier to integrate into existing production lines.

- Safety: They operate within a confined, structured area. This contained work environment reduces the chance of accidents and makes them safe for operation near human workers. Proper safeguards are still necessary, though.

- You can operate them with a single controller: This eliminates the need for interaction between multiple input devices.

- They move heavy payloads over long distances: Their long strokes of over two meters and high speeds can reduce cycle times.

When should I use a Cartesian robot?

As you probably know, there are many types of robotic arms and robots available, such as SCARA, Articulated, etc. But when is it best to just go for a good, old-fashioned Cartesian robot? For our money, Cartesian robots work best when speed, a high payload capacity, and precision are crucial, especially if you’re a bit limited in the space department. What’s this about space? The dual-arm configurations and stackable designs of cartesian robots reduce installation space. Meanwhile, their compatibility with various linear actuators and drive mechanisms (belt, ball or lead screw, pneumatic actuator, or linear motor) makes them adaptable requirements. Otherwise, more articulated Six-Axis robots could be the way to go, especially as tasks increase in complexity.

Conclusion

“What is a Cartesian robot?” Now you know. These programmable machines can help streamline and automate all sorts of manufacturing and assembly processes. While they may seem complex at first, understanding the fundamentals of their components, types, and how they work helps take away the mystery and understand their correct application. Of course, figuring out whether you need a Cartesian robot or another type of automated partner is going to take a thorough understanding of:

- The complexity of your operation.

- Your payload, reach, and speed needs.

- Your budget.

- Whether you need side-by-side operations with humans.

Post time: Nov-14-2024