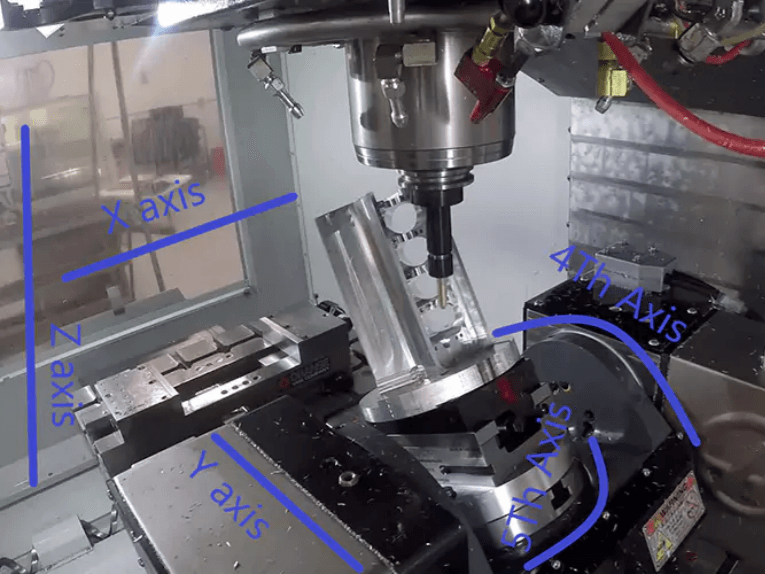

CNC machines commonly operate along three to five primary axes of movement:

1. X-Axis: This horizontal axis allows for lateral movement to the left and right. It is essential for positioning the cutting tool or workpiece in a precise horizontal location.

2. Y-Axis: Another horizontal axis, the Y-axis, enables movement forward and backward, crucial for accurate placement in the vertical plane relative to the X-axis.

3. Z-Axis: The vertical axis, Z, facilitates up and down movement. This axis is fundamental in controlling the depth of cuts in machining operations.

4. A-Axis: This rotational axis typically revolves around the X-axis. Implementing the A-axis allows machines to perform more complex shapes and angles by rotating the workpiece.

5. B-Axis: Another rotational axis, the B-axis, usually rotates around the Y-axis. Like the A-axis, it enhances the machine’s capability to tackle intricate geometries and sophisticated machining processes.

6. C-Axis: This axis rotates around the Z-axis and is often utilized in conjunction with the A and B axes, particularly in advanced machining centers for 3D contouring and precise milling procedures.

By understanding each axis and its role, professionals harness the full potential of CNC machines, ensuring precision, efficiency, and innovation in manufacturing processes.

Exploring the X-Axis in CNC Machines

As a foundational axis in CNC machining, the X-axis facilitates lateral movement, extending left and right across the machine’s horizontal plane. This axis is critical for positioning both the cutting tool and the workpiece with precision. Its accurate horizontal placement capabilities enable machinists to achieve intricate detailed cuts by meticulously controlling the linear motion. Precise command over the X-axis ensures that the integrity of the machining process is maintained, contributing significantly to the overall quality and precision of the final product.

Understanding the Role of the Y-Axis

The Y-axis in CNC machines is equally pivotal as the X-axis, providing vertical movement along the horizontal plane of the worktable. By enabling front-to-back motion, the Y-axis allows for comprehensive spatial navigation, crucial for executing precise and complex machining operations. The axis ensures that the cutting tool can maneuver around various points on the workpiece, thus facilitating multi-directional fabrication and intricate contouring.

In terms of technical parameters, the Y-axis typically features:

1. Resolution and Accuracy: High-resolution encoders are employed to achieve accurate positioning, usually within microns.

2. Travel Distance: The maximum travel distance on the Y-axis varies depending on the machine size, typically ranging from a few hundred millimeters to over a meter in industrial applications.

3. Load Capacity: Determined by factors such as ball screw diameter and motor torque, ensuring the Y-axis can handle significant loads while maintaining precision.

4. Feed Rate: The speed at which the Y-axis can traverse, typically measured in mm/min, designed to optimize both efficiency and accuracy during operations.

Understanding these parameters allows machinists to maximize the Y-axis potential, ensuring high-quality production and extended machine longevity.

The Function of the Z-Axis in CNC Milling

The Z-axis is integral to CNC milling, providing vertical movement perpendicular to both the X- and Y-axes. This axis controls the up-and-down motion of the cutting tool or spindle, enabling depth control in machining operations. Understanding the precise function and technical parameters of the Z-axis is crucial for achieving optimal milling performance.

In CNC milling, the Z-axis encompasses the following technical parameters:

1. Resolution and Accuracy: Utilizes high-resolution encoders to ensure precise vertical positioning, usually within microns, critical for achieving detailed and accurate vertical cuts.

2. Travel Distance: The maximum travel distance on the Z-axis depends on the machine configuration and size, generally ranging from 100mm to over 600mm in heavy-duty industrial machines.

3. Load Capacity: Determined by the spindle’s strength and the structural rigidity of the machine. Factors such as motor torque and ball screw diameter play a pivotal role here, allowing the Z-axis to handle significant vertical loads without compromising accuracy.

4. Feed Rate: The vertical feed rate indicates how quickly the Z-axis can move up and down, typically measured in mm/min. This rate is optimized to balance speed and precision, ensuring efficient material removal without causing undue stress on the machine components.

Equipped with a thorough understanding of the Z-axis and its capabilities, operators can utilize CNC machines to create intricate and high-precision components, enhancing both productivity and product quality.

Post time: Apr-08-2025