How to Select and Apply Rail Brakes

The servo and stepper motors that drive linear motion systems often include a braking function, or, in the case of stepper motors, detent torque that helps prevent the motor (and, therefore, the load) from moving when powered off. But in some applications, a secondary brake is required — either to provide redundancy and meet safety requirements or to hold the load accurately, without hunting or dithering, while an external process takes place. For systems that use profiled rail guides, rail brakes are often the best choice.

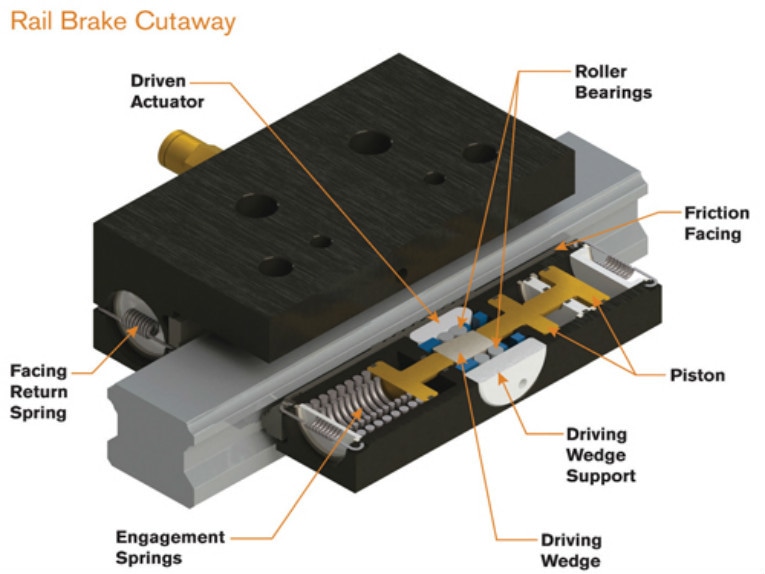

Rail brakes work through spring forces, fluid media, or a combination of the two, to engage and disengage friction pads with the sides of the profiled rail. For example, one design uses spring force to engage the friction pads and pneumatic force to release them. Another design uses hydraulic force for both engagement and disengagement.

Manufacturers offer rail brakes in both normally open designs (sometimes referred to as active designs), where the brake or clamp is open, or disengaged, until activated via pneumatic, hydraulic, or another force — and normally closed designs (also referred to as passive designs), where the brake or clamp is engaged until a force is applied.

To avoid wear on the profiled rail, rail brakes are designed to engage on the non-load-bearing surfaces of the rail profile. And since rail product lines from various manufacturers — and even different product lines from the same manufacturer — have different profiles, rail brakes are designed accordingly. That is, each brake is designed to fit a specific product line from a specific manufacturer.

When selecting a rail brake, the first step is to select the correct brake model for the rail it will be used with. Then, from the available options to fit a specific profiled rail, choose the brake that provides the holding force required. Remember that in some cases, the holding force should include the load and external processing forces (such as drilling) that will be applied to the load. Also keep in mind that if the load is in a vertical or inclined orientation, the brake will need to hold the load against the force of gravity. Stopping time is also an important selection parameter — particularly when the brake is intended for use in emergency-stop conditions. The faster the brake can bring the load to a stop, the shorter the distance traveled, and the lower the likelihood of damage.

It’s important to note that rail brakes are not designed for repeated, dynamic stopping. Instead, they’re typically intended for precision holding during regular process stops, allowing the brake to be sacrificed rather than subject the load or equipment to forces from shock loads. They can also be used as redundant braking devices or for infrequent emergency stops.

Post time: Jan-04-2021