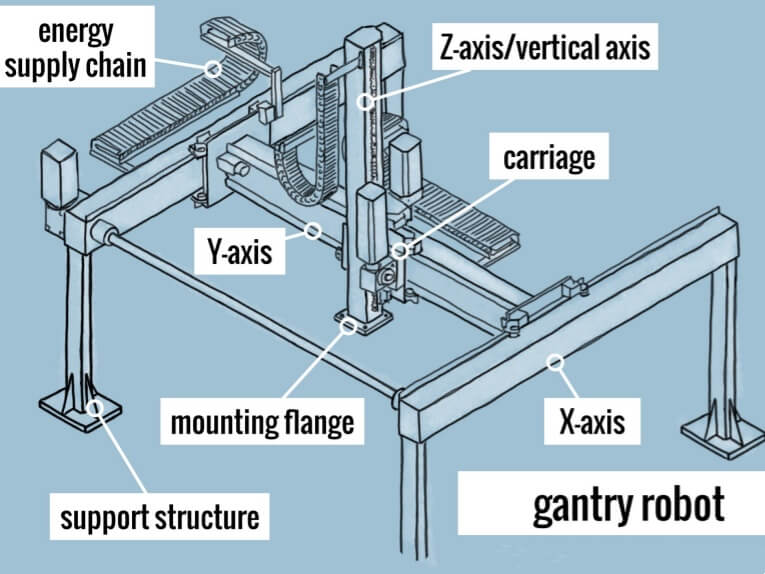

A gantry robot is a robot that can move across the full area of a machine. The robot has a cube-shaped operating range. As the gantry robot is placed in a machine above the objects, it has complete freedom of movement and is not constrained by specific footprints.

How gantry robot work

The gantry robot has three guides: for movement along the X axis, along the Y axis, and along the Z axis. The robot can move back and forth along the X axis and Y axis and up and down from top to bottom along the Z axis. This enables the robot to access an entire room within the work area.

Use of gantry robot

Gantry robots can be used in all markets. The robot can pick and place products spread over the entire work area. As the gantry robot operates from above, its location and other installations do not hinder it from reaching the right products. Picking up and moving products can cause ergonomic problems in operators. A gantry robot allows the operator to take on a supervisory role instead of having to lift the products themselves.

Advantages of our gantry robot

- It can move a wide range of products quickly and efficiently;

- As the gantry robot is positioned above the area of work, it can easily reach all the corners of the work space;

- The gantry can be freely configured to any desired work area;

- Fewer ergonomic problems.

Gantry benefits for your project

- Increase speed of material handling/ palletizing improves productivity

- Can handle heavy-weight items and transfer them at lifting height

- Can handle variations in products and proliferation

- Improve quality and consistency

- Increase safety by reduced operator handling and eliminate the use of overhead crane and forklifts

- System reduces risk for employees’ subject to repeatable movement

- No external lubrication required. All lubrication in gears and track conveyor are food grade.

- Easy to measure the return of investment

- Allows for 24 hour operation with minimum staff and 365 days per year due to the robust/reliable design

Powerful, minimal maintenance and flexibel applications

Gantry robots are excellent for handling heavy payloads, part loading and unloading, and precise picking and placement in manufacturing environments. Our company offers gantry robots with a smart design that optimizes production flow. Our sophisticated interpolating motion systems enable limitless options for high speeds, long strokes, heavy payloads, and high positioning accuracy. In addition, we can easily incorporate special requirements for harsh environments or low noise. In addition, our gantry robots feature advanced lubrication-free toothed belt drives, which are superior to traditional rack and pinion drives. They require no oil or grease maintenance, ensuring maximum uptime and productivity.

Post time: Aug-07-2024