Manufacturers have several options for electronics manufacturing automation. There are a few robot types commonly found in these applications:

1. Collaborative

2. Cartesian

3. SCARA

4. Six-axis

Collaborative

Collaborative robots are common choices for electronics manufacturers. Electronics production tasks are often small, lightweight, and can work close to people. The characteristics of tasks like these both take advantage of the strengths of collaborative robots (hybrid working environments) while keeping the requirements within the limits of what collaborative robots can do. Cobots excel in hybrid environments and are easily redeployed in other applications with limited expertise required.

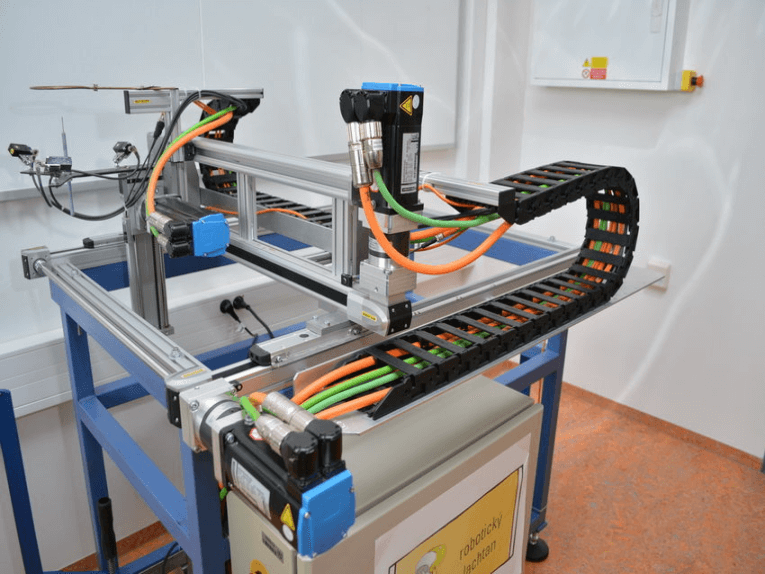

Cartesian

Cartesian robots are known for their high levels of precision. This is due to their rigid and straightforward construction. Cartesian applications often require manual loading by a technician. This type is highly scalable but lacks the dexterity and flexibility of other types on this list.

SCARA

The SCARA is a common choice for electronics applications due to its blend of precision, speed, and reach. This type can move quickly from point to point without sacrificing precision. Like the cartesian robot, it can struggle with flexibility and tasks that require complex motion. However, it’s one of the fastest and most affordable options available.

Six-axis

The six-axis robot is deployed the broadest array of applications compared to other robot types. Because of this, it makes sense that it would be heavily represented in electronics manufacturing. It can be a more expensive option, but for certain tasks like those that require complex motion, the six-axis robot becomes a clear choice.

Post time: Mar-13-2023