When sizing and selecting linear motion systems for assembly machines, engineers often overlook critical application requirements. This can lead to costly redesigns and rework. Worse yet, it can result in an overengineered system that is more costly and less effective than desired.

With so many technology options, it’s easy to become overwhelmed when designing one-, two- and three-axis linear motion systems. How much load will the system need to handle? How fast will it need to move? What is the most cost-effective design?

All these questions were considered when we developed “LOSTPED”-a simple acronym to help engineers gather information for specifying linear motion components or modules in any application. LOSTPED stands for load, orientation, speed, travel, precision, environment and duty cycle. Each letter represents one factor that must be considered when sizing and selecting a linear motion system.

Each factor must be considered individually and as a group to ensure optimal system performance. For example, the load imposes different demands on the bearings during acceleration and deceleration than during constant speeds. As linear motion technology evolves from individual components to complete systems, the interactions between components-such as linear bearing guides and a ballscrew drive-become more complex and designing the right system becomes more challenging. LOSTPED can help designers avoid mistakes by reminding them to consider these interrelated factors during system development and specification.

Load

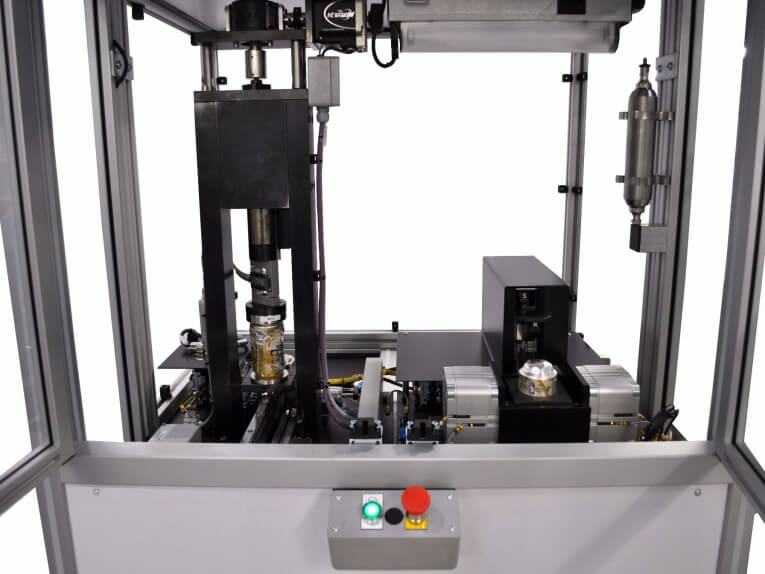

Load refers to the weight, or force, applied to the system. All linear motion systems encounter some type of load, such as downward forces in material handling applications or thrust loads in drilling, pressing or screwdriving applications. Other applications encounter a constant load. For example, in a semiconductor wafer-handling application, a front-opening unified pod is carried from bay to bay for drop-off and pick-up. Other applications have varying loads. For instance, in a medical dispensing application, a reagent is deposited in a series of pipettes one after another, resulting in a lighter load at each step.

When calculating the load, it’s worth considering the type of tool that will be at the end of the arm to pick up or carry the load. Although not specifically related to load, mistakes here can be costly. For example, in a pick-and-place application, a highly sensitive workpiece could be damaged if the wrong gripper is used. Although it’s unlikely that engineers would forget to consider the general load requirements for a system, they may indeed overlook certain aspects of those requirements. LOSTPED is a way to ensure completeness. By focusing on these key parameters, engineers can design an optimal, cost-effective linear motion system.

Key questions to ask:

1. What is the source of the load and how is it oriented?

2. Are there special handling considerations?

3. How much weight or force must be managed?

4. Is the force a downward force, a lift-off force or a side force?

Orientation

The orientation, or relative position or direction in which force is applied, is also important, but it’s often overlooked. Some linear modules or actuators can handle higher downward or upward loading than side loading because of their linear guides. Other modules, using different linear guides, can handle the same loads in all directions. For example, a module equipped with dual ball-rail linear guides can handle axial loads better than modules with standard guides.

Post time: Feb-05-2024