Robotic laser cutting offers some useful benefits over more conventional forms of laser cutting automation. But, you might still be unsure if it’s the best approach for you.

Why would you choose to use a robot instead of a laser cutting machine?

What are the disadvantages of opting for a more conventional machine?

The new age of robotic laser cutting has already arrived. Here is the key information you need to decide if it’s the right choice for your business.

The Conventional Approach: Laser Cutting Machine

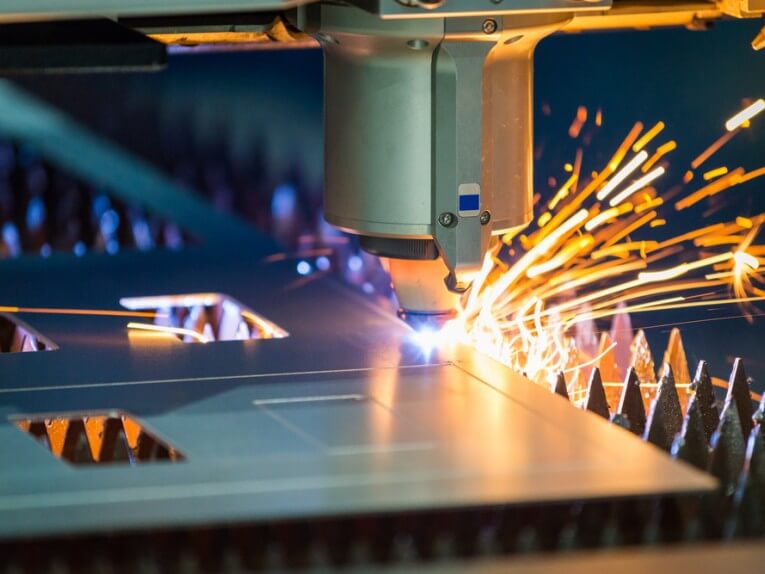

Automated laser cutting is nothing new. Most machine shops and many manufacturing facilities already have a flatbed laser cutting machine.

Laser cutting is used in a wide variety of industries including automotive, jewelry manufacture, and silicon manufacturing.

Flatbed laser cutting machines are extremely useful. They are very versatile compared to more traditional forms of cutting, such as band saws and water jet cutting. They can be used for both cutting and surface etching.

Despite their versatility, conventional laser cutting machines are not always ideal.

For one thing, they are often expensive. Commercial laser cutting machines can range from $20,000 to $250,000 or even more. Even if this is a reasonable price for the return you will get, the problem is that the machines are only suitable for one particular task — cutting on a single plane.

You need to be cutting a large number of products each day to justify the expense of such a machine.

The Disadvantage of Using Laser Cutting Machines

There are other potential disadvantages of using conventional laser cutting machines.

Limitations of laser cutting machines include:

1. Single purpose — As mentioned above, a laser cutting machine is essentially single purpose. It can only cut or etch on a single plane.

2. They’re huge — A laser cutting machine can easily take up a whole section of a machine shop. This means that investing in a conventional machine also means giving up considerable amounts of floor space.

3. They require supervision — Like many CNC machines, laser cutters aren’t completely autonomous. They require supervision from a skilled operator. This adds to the cost of using a machine as you also need to factor in the salary of those supervising workers.

Want to perform cutting tasks? You need multiple machines

The limitations of each individual laser cutting machine add an extra disadvantage that people often don’t realize.

They mean that companies often need to buy multiple laser cutting machines to achieve particular tasks. For example, you might use different machines to cut different shapes of parts.

This significantly adds to the budget and space required to use laser cutting machines. Like many manufacturers, you might start by assuming that you only need one machine only to realize later that you will need several.

Post time: Feb-13-2023