5 Differences Between Robots and CNC Machines

Besides the tasks you can achieve with them, there are performance and quality differences between the two technologies.

Here are 5 of them:

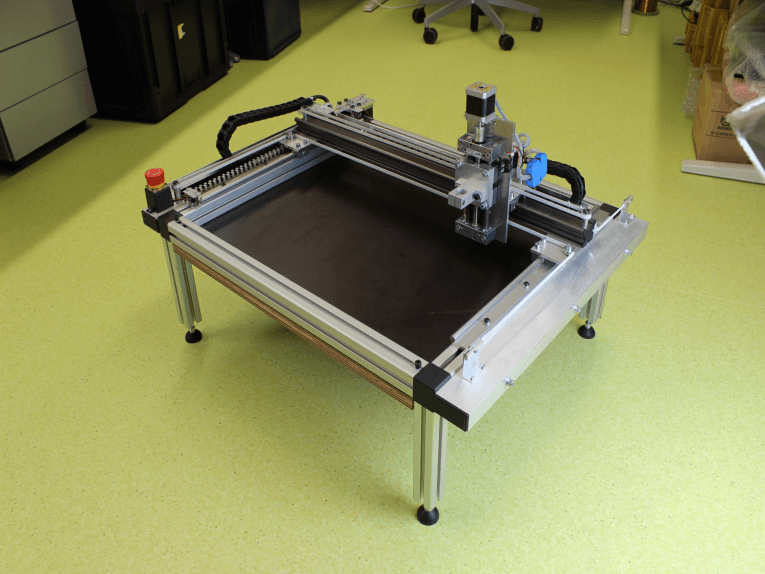

Workspace — The workspace of a CNC machine can usually be defined as a small cube. Robots, by contrast, usually have a large, spherical workspace.

Programming — CNC machines are programmed using G-Code. These days, this is most often generated by a CAM software, not coded by hand. Robots are programmed using a manufacturer’s programming language, but programs can be generated by many other programming methods (including G-Code) via a robot post-processor.

Accuracy — CNC machines are usually more accurate than robots with accuracies going down to fractions of a micron. Robot accuracies can be improved by calibration but are more likely to be 100s of microns.

Stiffness — CNC machines usually have high stiffness in all axes. The stiffness of robots is generally lower but it varies depending on the type of robot — e.g. a Scara robot has high stiffness in the Z axis.

Singularities — The position of a robot tool is usually calculated by an inverse kinematics algorithm. These can produce singularities — areas of the workspace which are basically “dead zones” caused by mathematics within the algorithm.

Post time: Mar-19-2024