-

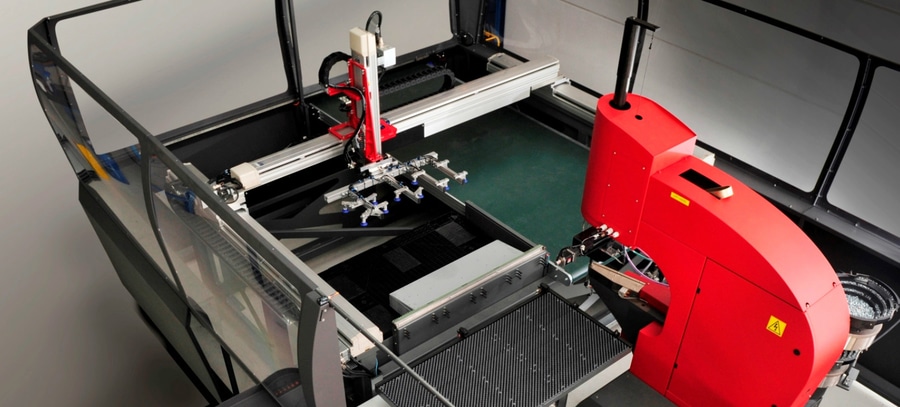

10 Benefits of Using a Pick-and-Place Machine

The road to improved productivity and product quality often starts with pick-and-place automation. Pick-and-place machines have become an essential part of the modern manufacturing environment, offering customizable ways to solve problems and ultimately bolster companies’ bottom lines. Here are ...Read more -

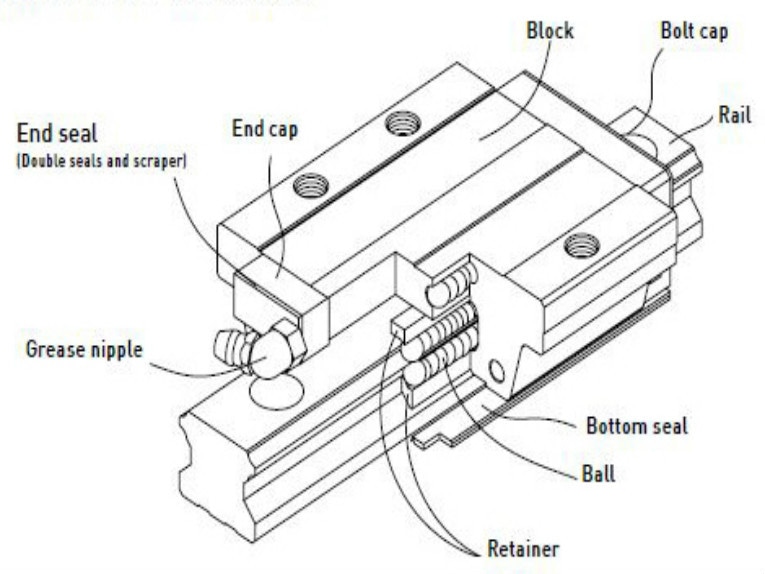

What Makes a Linear Guide Suitable for High Temperature Use?

Metal components, Plastic components, Lubrication, Optional components and accessories. For most recirculating ball and roller linear guides, the allowable operating temperature range is -10° to 80° C, with some configurations rated up to 100° C for brief periods. But not all applications fall w...Read more -

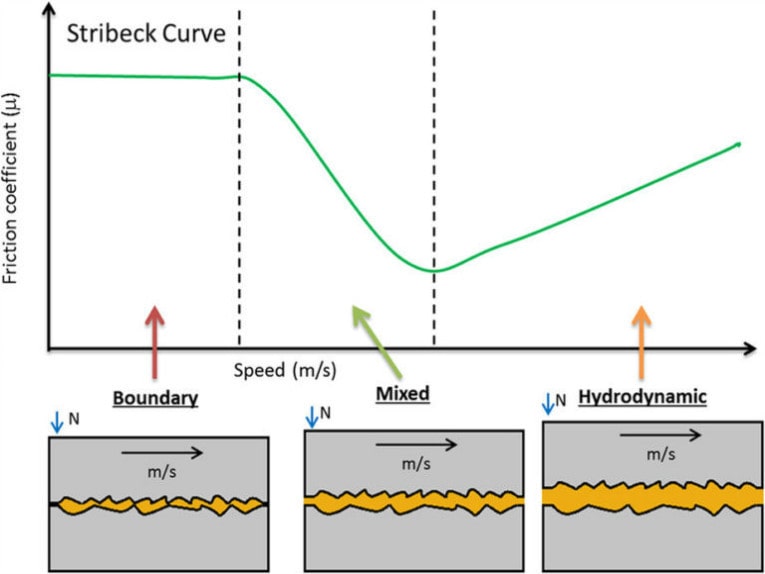

How to Reduce the Effects of Stiction (stick-slip) in Linear Guides

What causes stiction? How to reduce them. Unless you’re playing the violin, stiction, or stick-slip, is an unwanted condition caused by the difference between static and dynamic friction between the two surfaces. When stiction occurs in linear guides, it can lead to chattering (“jerky” motion), ...Read more -

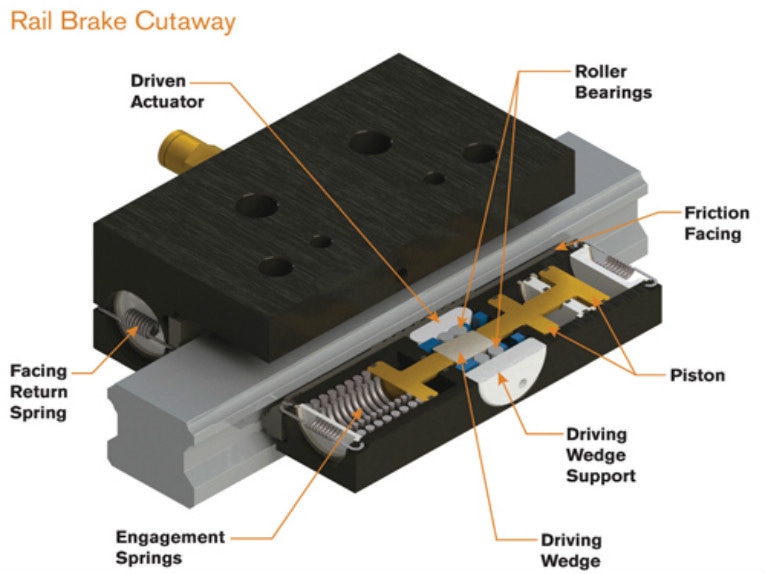

What are Rail Brakes and When Should You Use them?

How to Select and Apply Rail Brakes The servo and stepper motors that drive linear motion systems often include a braking function, or, in the case of stepper motors, detent torque that helps prevent the motor (and, therefore, the load) from moving when powered off. But in some applications, a s...Read more -

How to Specify Pulleys for Synchronous Belt Drives

High speed and precision belt driven system design. When designing a belt drive system, the first step is to choose the most suitable belt for the application. But the pulleys also play an important role in the performance of the belt — especially in synchronous belt drive systems, where proper ...Read more -

Pushing the Limits of Linear Accuracy

Straight, accurate movement is far from easy. Straight, accurate movement is far from easy, and linear positioning devices prove it by erring in not one, but three dimensions Just when you thought you had the “linear motion” concept nailed down – hit the required points on the straightaway and y...Read more -

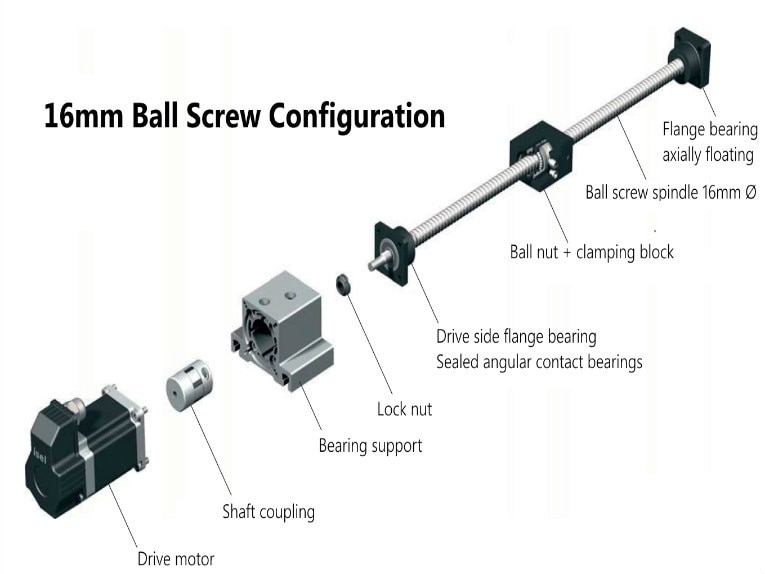

What Options are There for Integrated Motor and Screw Designs?

External motor-screw integration, Non-captive motor-screw integration and Captive motor-screw integration Ball and lead screw assemblies are often driven by a motor connected in-line with the screw shaft via a coupling. While this mounting arrangement is simple and easy to service, the addition ...Read more -

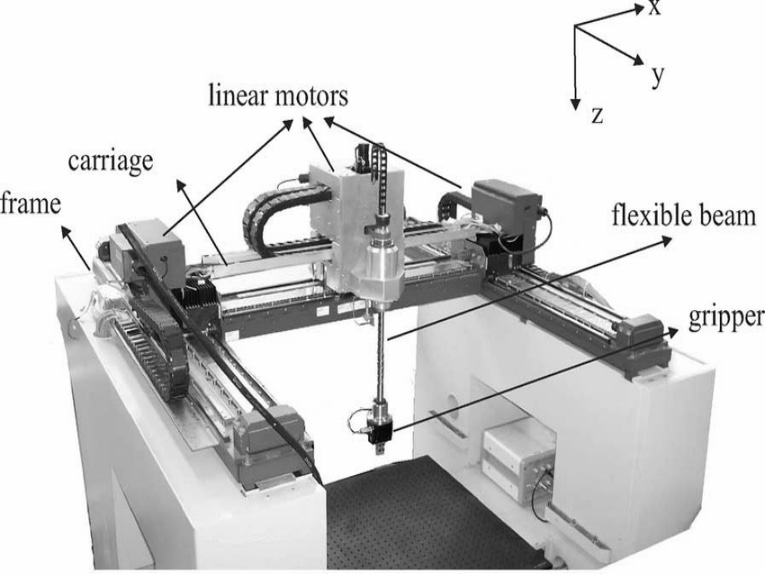

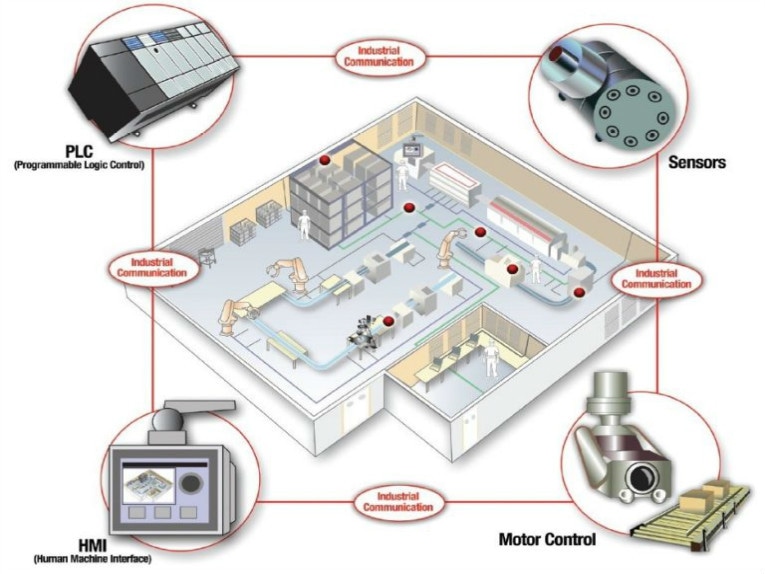

Three important design considerations for Cartesian robots

System configuration, Cable management, Controls. If your application calls for a Cartesian robot, you have a wide variety of options, depending on the level of integration you want to undertake. And although pre-engineered Cartesian robots are becoming more widely adopted as manufacturers expan...Read more -

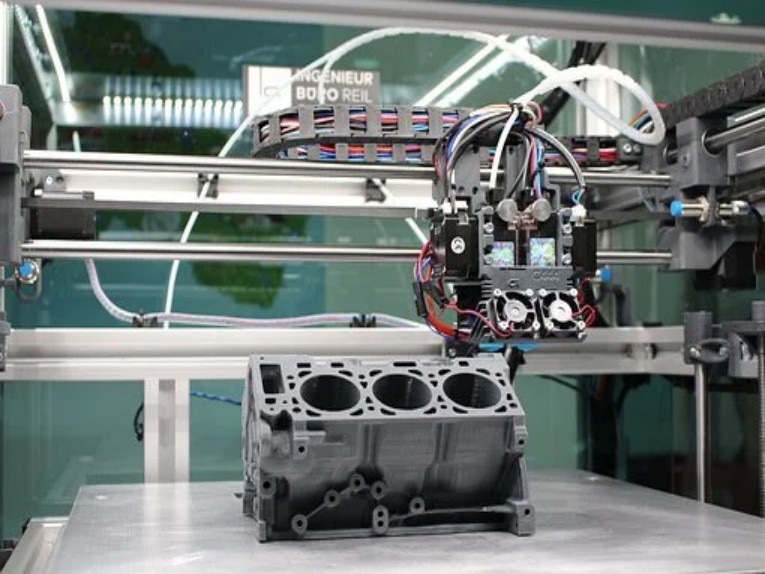

Linear Guides, Power Transmission, Actuators See Unexpected Applications

More precision and ease installation. Our 2020 survey of the industry indicates an unabated trend towards more automation of previously static or manually tended systems. Key to these new offerings is installation simplicity for OEMs and end users of linear components for linear axes … as well a...Read more -

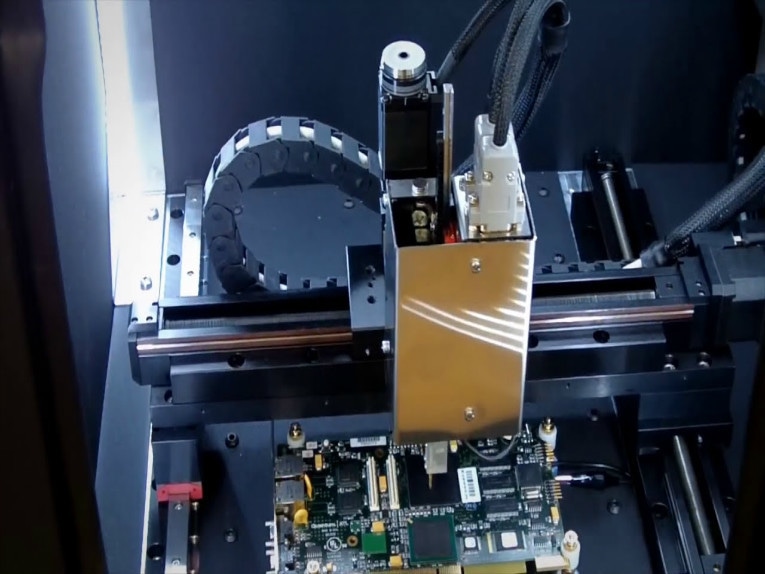

Linear Positioning Stages and XYZ Tables

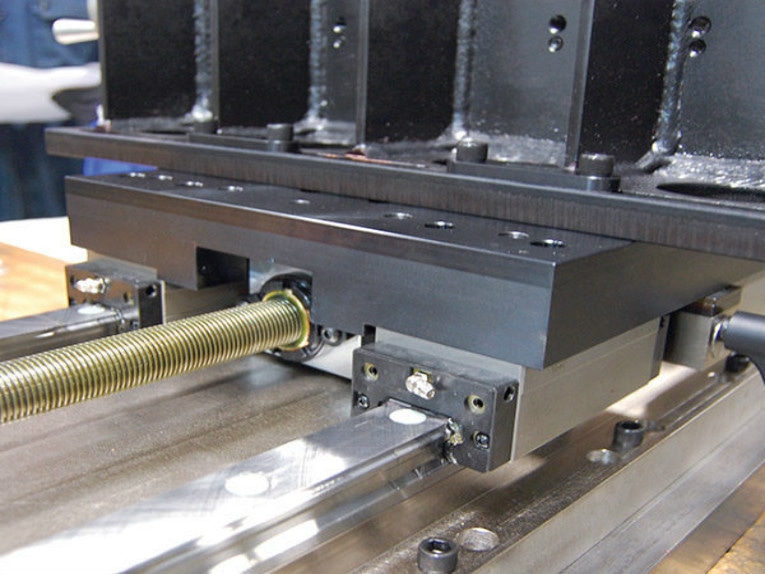

Cartesian Robot for Pick and Place Application. Positioning stages and tables are used in motion control systems to hold down a work piece and/or to position it for some operation. Stages or tables, whether linear or rotary, are most often complete motion sub-systems. That is, they are motion sy...Read more -

Rules for Actuator and Guide Alignment in Linear Motion Systems

Following a few simple guidelines for designing linear motion systems can improve system performance and actuator life. Many automated machines rely on linear guidance components, such as profiled rail, round rail or other rolling or sliding bearing structures, to guide and support the moving el...Read more -

Linear Motor vs. Ball Screw

The Cost-efficient Application for Your Own Design. While ironless linear motors have been used in semiconductor and electronic applications for more than a decade, they are still viewed by many designers and OEMs as “niche” products. But the perception of linear motors as a costly solution for ...Read more