-

Linear Systems for Nanopositioning

Piezo actuators, Voice coil actuators, Linear motor stages. When we talk about linear motion, we typically discuss applications where the travel distance is at least a few hundred millimeters, and the required positioning is in the range of a few tenths of a millimeter. And for these requirement...Read more -

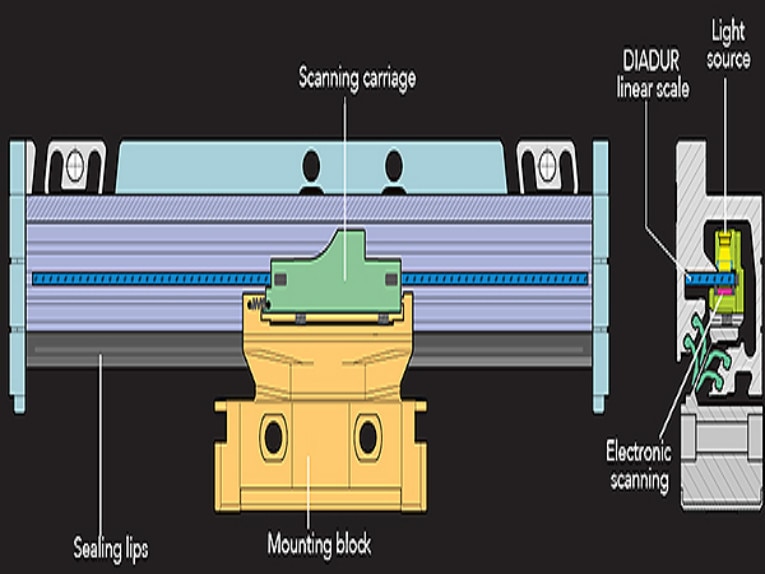

FAQ: What types of linear encoders are there and how do I choose?

Absolute or incremental, Optical or magnetic. Linear encoders monitor linear movement and provide position feedback in the form of electrical signals. In servo driven systems, linear encoders supply the precise position of the load, typically in addition to the speed and direction feedback provi...Read more -

What To Do When Your Motion System Throws You a Curve

Guide-wheel based ring and track systems are more compact and offer better positioning accuracy and more options for cargo carrying positions than alternative conveyor systems for curvilinear applications. In the ongoing drive to reduce production costs, one trend at manufacturing facilities is ...Read more -

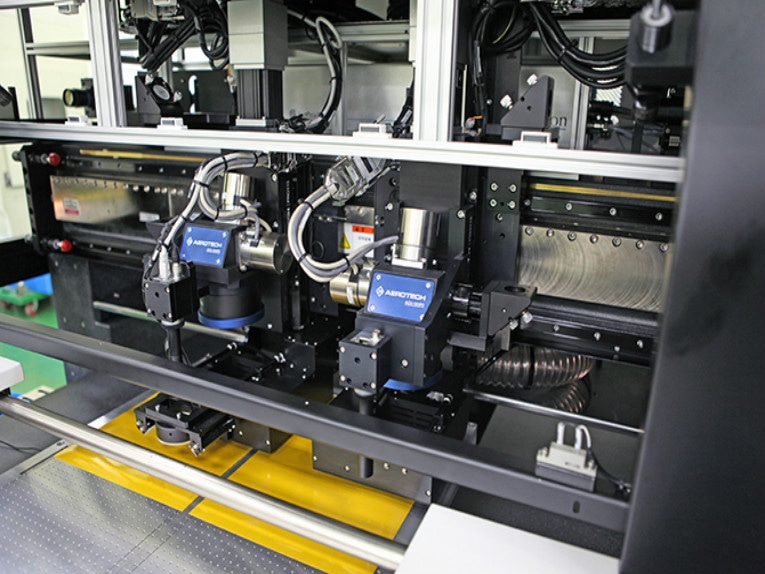

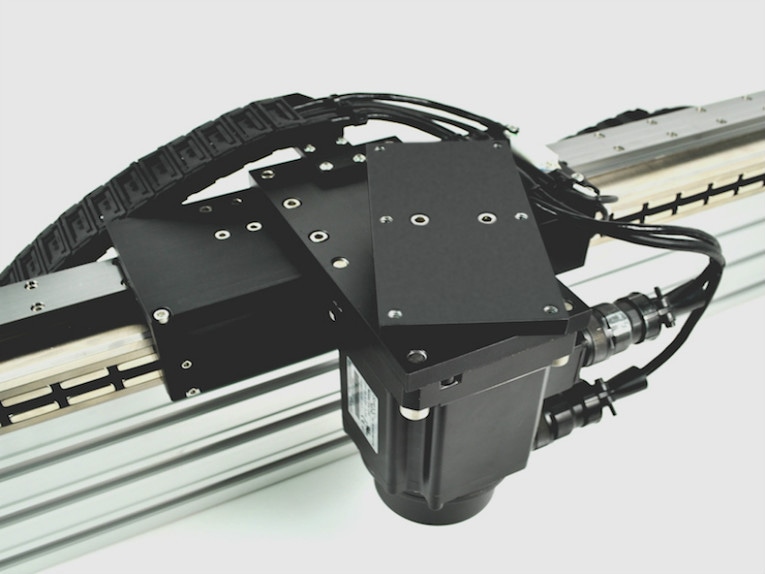

Positioning stages and gantries — new trends in integration approaches

The linear, rotary, XY, or vertical-lift stage integrates motor, drive, and controller. There’s demand for motion designs offering simplicity or turnkey operation, so component suppliers are now doing much more integration for OEMs and plant engineers. Nowhere is this more evident than in the wa...Read more -

Simple support structure improves warehouse packaging efficiency

An improvement in packaging efficiency required attention to ergonomics, ease of assembly, and cost efficiency. Automation is changing how traditional distribution centers operate as companies search for new ways to maximize their efficiency, increase order accuracy and fulfill customer demand. ...Read more -

What is an LED Matrix Screen?

High-end LED Billboard Subversives. The dynamic ups and downs of each module of the fuyu LED matrix screen combine with the video screen to form different creative combinations. The terminator of two-dimensional plane advertising leads the epochal wave of media replacement and advertising apprec...Read more -

How to estimate your linear actuator needs with minimal application data

Load, Accuracy, Speed and Travel. Choosing linear motion components during the development phase of a project has been a source of frustration for designers and application engineers for decades—especially when it comes to complex subassemblies such as linear actuators. Consider for a moment the...Read more -

Which type of linear actuator is best for thrust forces?

Electromechanical designs in motion control applications. When an application requires pure thrust forces, the best type of linear actuator is often a rod-style actuator. Also referred to as “thrust actuators” and (when a motor is integrated) “electric actuators,” these electromechanical devices...Read more -

Linear Actuators: the Make vs. Buy Decision

Business evaluation, Manufacturing and assembly requirements, Customer support needs. With the range of linear actuators on the market, it’s becoming easier for machine builders and end users to find a standard or “customized standard” product that meets even the most unique application requirem...Read more -

Actuator Basics: Five Different Technologies Integrated into One Package

Motive power source, means of transmission, bearing or guidance, frame or support structure, position feedback (in most cases). Another area of Mechatronics that is very confusing is the area of actuators. The problem is that you can buy actuators that are assemblies of several components, or yo...Read more -

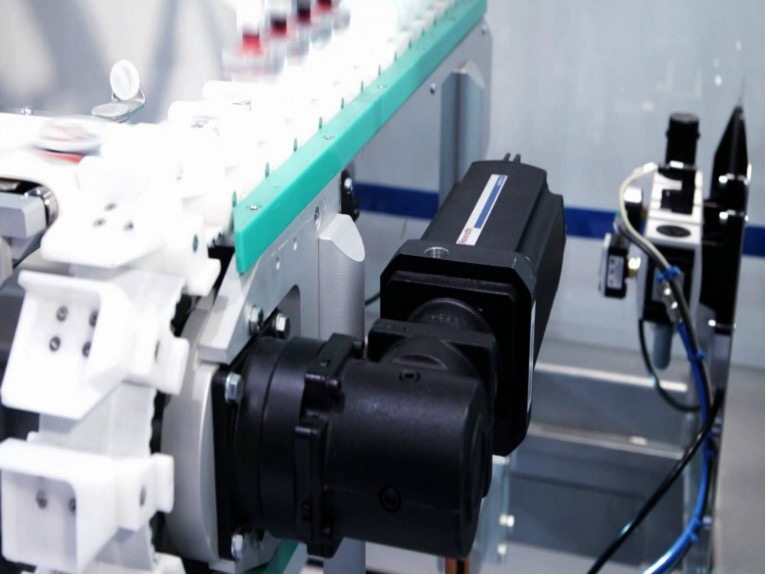

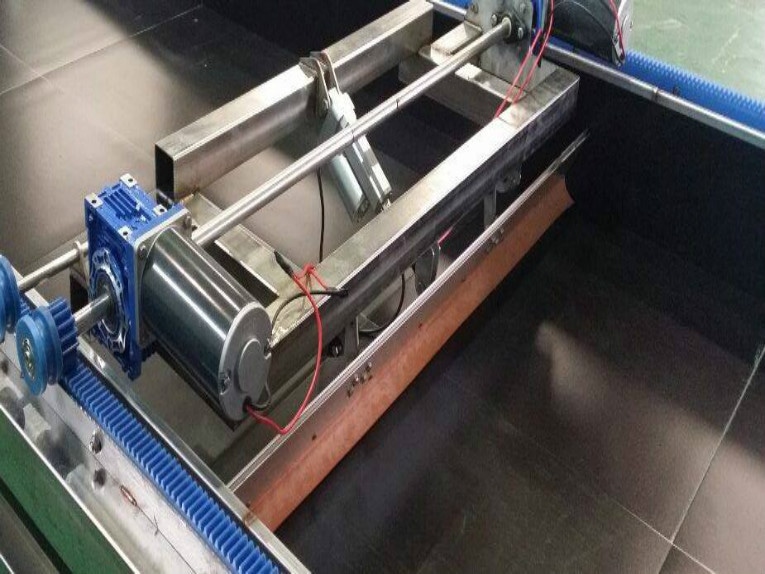

What are some considerations for linear actuators in contaminated environments?

A typical contaminated environment is shown here. Reliable motion is often difficult to obtain when the operating environment is heavily contaminated with debris, or contains extreme conditions such as a wide temperature range or other environmental factors.The use of machinery for operations su...Read more -

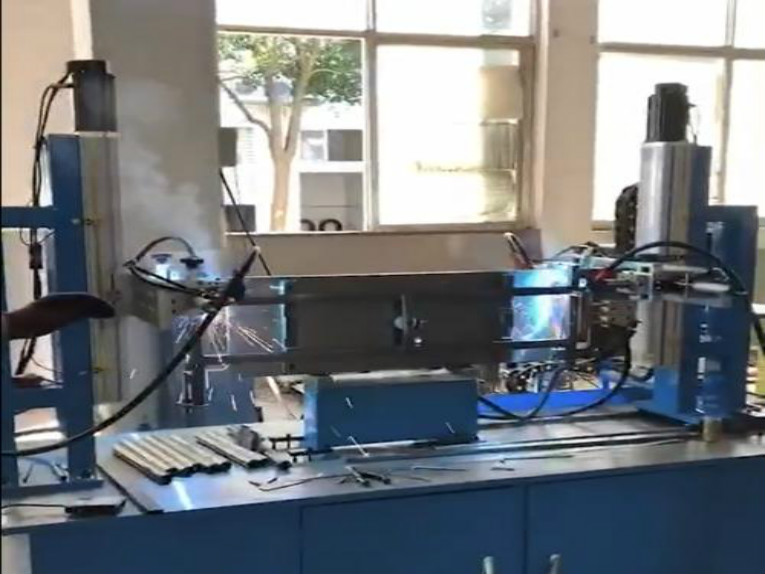

High speed linear actuators: What qualifies them as high speed?

Screw diameter, length, or end bearing arrangement. Like many terms used in the linear motion industry – “heavy duty,” “miniature,” and “corrosion-resistant,” to name a few – there is no industry standard that specifies what constitutes a “high speed” linear actuator. Nevertheless, there are som...Read more