-

FUYU 10th Anniversary New Start New Journey 2011-2021

On January 18, 2022, Fuyu Technology celebrated its first 10th anniversary. At the meeting, Mr. Cao Zhiming, the general manager, expounded on Fuyu’s own strategy in the past 10 years. The company has agreed on the goal of “the global leader in linear modular motion systems”. I...Read more -

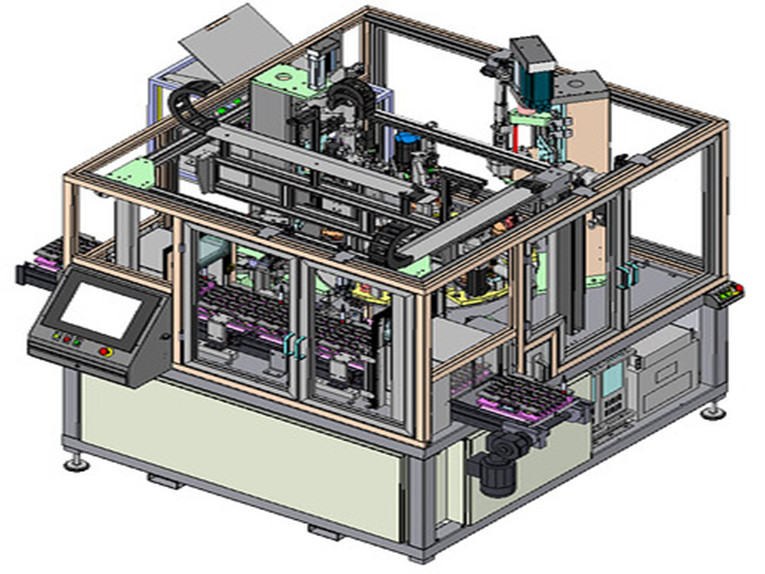

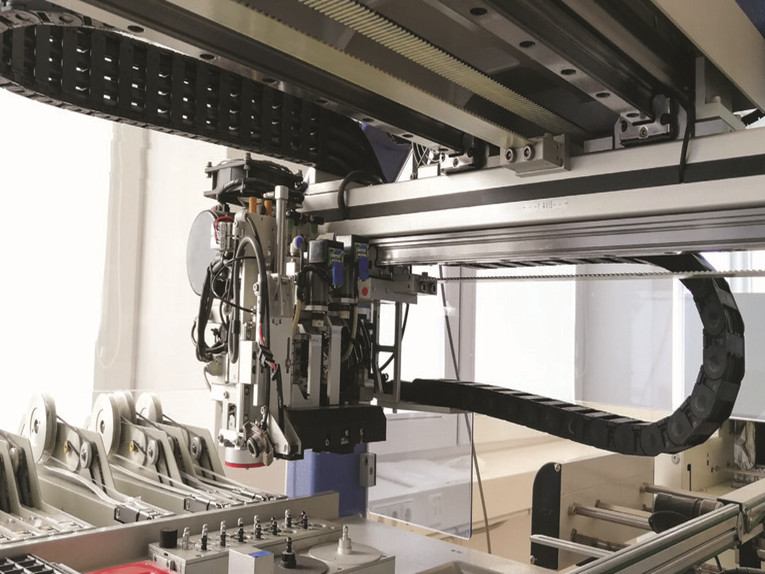

Gantry Systems: Working Outside the Envelope

Application / Industry: Packaging, production, palletizing, pick and place, automation. The Challenge: The irregular work envelopes of traditional jointed articulating arms may require redesign of existing workspaces. SCARA and articulating arm robots might be the most recognizable form of robot...Read more -

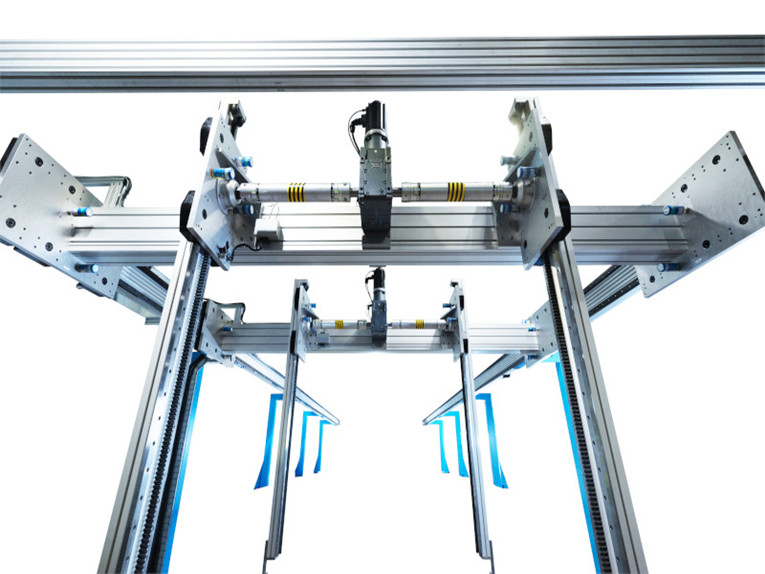

What is a split bridge system and how does it differ from a gantry?

Multi-axis linear systems come in a variety of designs, with Cartesian, gantry, and XY tables being some of the most common types. While these designs simplify construction and can provide space savings, they also introduce “stacking” errors — the compounding of errors from each axis, which mani...Read more -

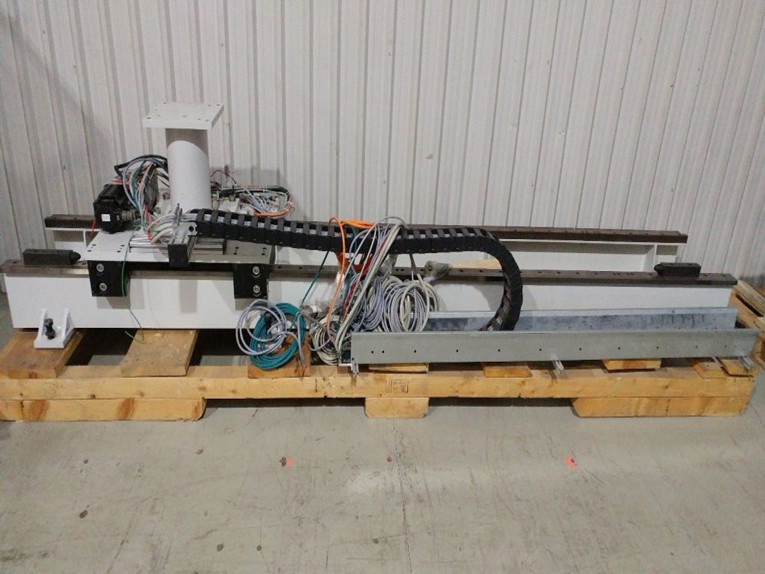

Designing linear motion tracks for robotic positioning

Robot positioning systems are long tracks in warehouse, aerospace, and automotive facilities to let one robot perform multiple tasks. Also called robot-transfer units or RTUs or 7th-axis systems, these motion designs are increasingly common for assembly, large-scale welding, and warehousing. In ...Read more -

Three easy ways to specify application requirements for linear motion systems

The first step in any automation project is to clearly define the objective — what process are you trying to accomplish or what output are you trying to produce? Once the process or output is defined, it’s time to dig into the details of the application so you can choose the right components or ...Read more -

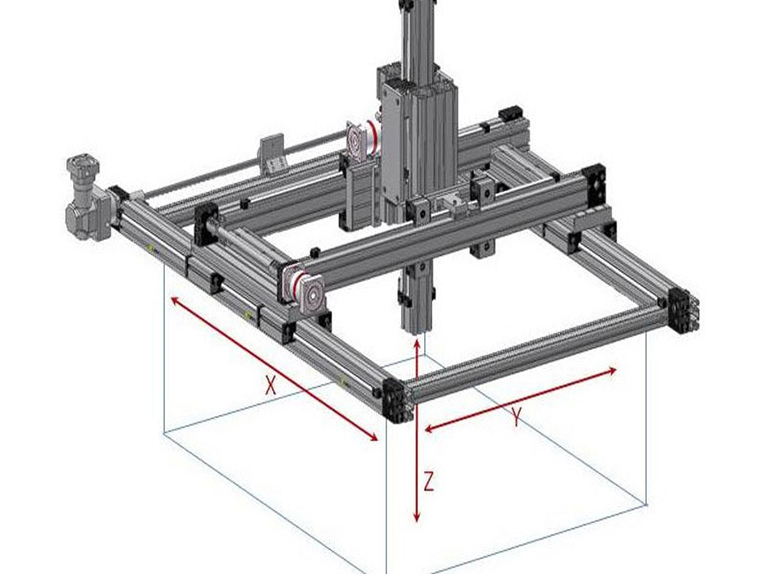

What are Cartesian Robots?

Cartesian coordinate geometry is an excellent method for mapping three-dimensional space in a simple, easy-to-understand numerical system. In the Cartesian system for three-dimensional space, there are three coordinate axes that are perpendicular to each other (orthogonal axes) and meet at the ...Read more -

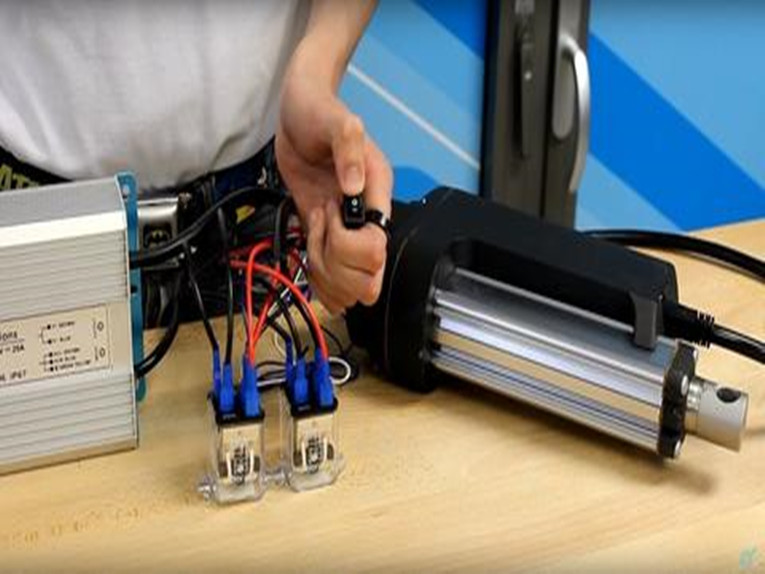

What is a 12 volt linear actuator?

Linear actuators are typically characterized by their drive mechanism – belt drive, ball or lead screw drive, pneumatic drive, etc. But it’s not unusual for rod style electric actuators to be classified by the input voltage – commonly 12 or 24 volts – of their integrated motors. These actuators ...Read more -

Gantry systems: the perfect solution for heavy loads and larger work areas

Automation in the manufacturing industry is continuing to grow in demand and can be applied to nearly every application from processing, assembly, inspection to packaging. Gantries and 6-axis industrial robots are widely used to achieve automation for applications such as palletizing, sorting, a...Read more -

WHAT TO KNOW ABOUT PICK AND PLACE ROBOTS

Haven’t most of us, during childhood, once hoped for a robot that could pick up our toys, place them back and organize them so that our parents wouldn’t scold us for making a mess? Today, it has become reality. Although robots are not yet picking and placing items in our homes, they are doing ...Read more -

What are Linear Actuators and Their Applications?

A linear actuator is a device used to move or control the circular motion linear-direction using a centralized control signal. The control signal helps the motor to move forward and backward any mechanism in a straight line. The pull and push motion enables the device to perform multiple functio...Read more -

Rules for Actuator and Guide Alignment in Linear Motion Systems

Following a few simple guidelines for designing linear motion systems can improve system performance and actuator life. Many automated machines rely on linear guidance components, such as profiled rail, round rail or other rolling or sliding bearing structures, to guide and support the moving el...Read more -

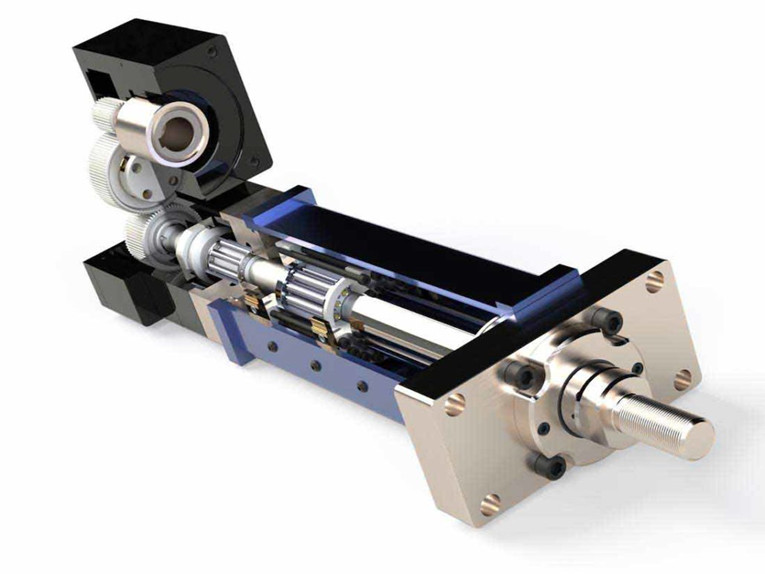

What are Linear Actuators and How are They Sized?

Linear actuators provide important functions to a range of medical devices such as medical beds, operating tables, and dental chairs. A linear actuator is a mechanical device that converts energy to create straight-line motion to either lift, tilt, or move mechanical legs in and out, depending o...Read more