-

Total cost of ownership for linear motion

You may not realize it, but many of the products you buy actually cost a lot more than the initial price you paid for them. For example, let’s say you paid $25,000 for your vehicle. How far do you drive and how many gallons of gasoline do you use each week? How often do you change the oil,...Read more -

A Guide to Stainless Steels for Linear Motion Components

For applications that involve corrosive environments, designers of linear motion systems can take precautions such as using covers to protect vulnerable components, ordering parts with special coatings or platings, and strategically placing sensitive components within the machine or system to mi...Read more -

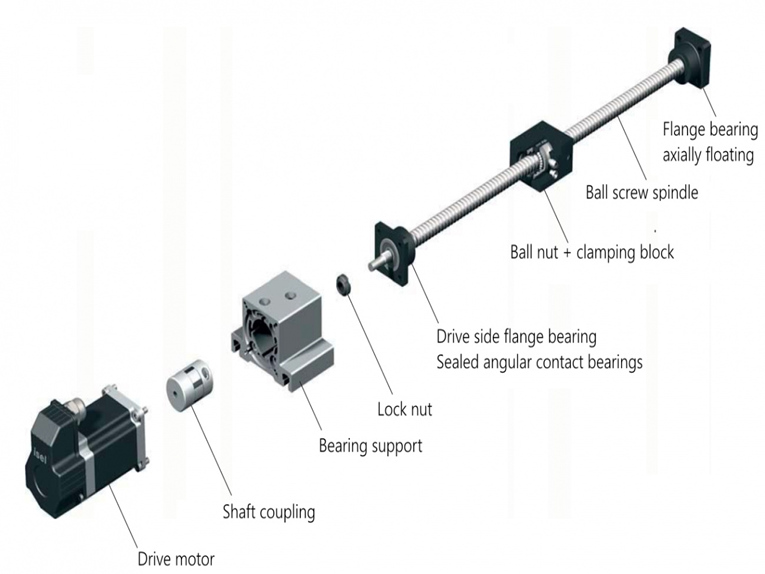

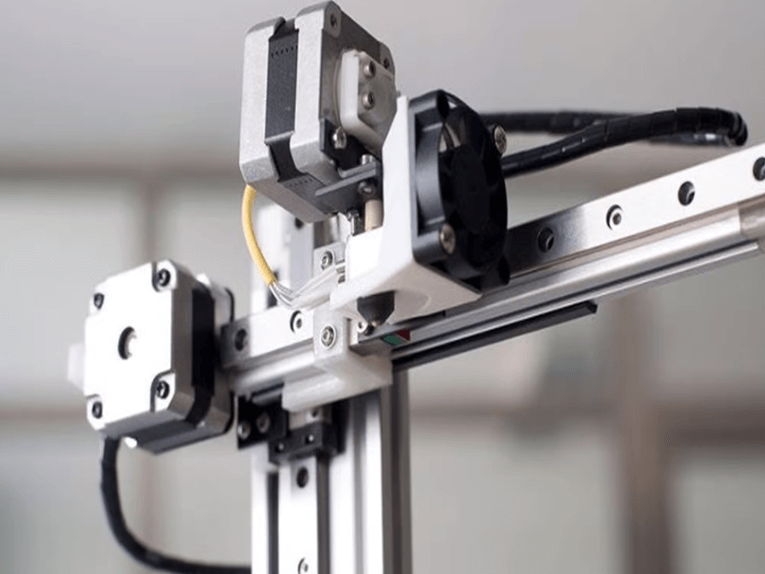

What is Linear Motion Design Engineering? Technical Summary.

Linear motion is an area of motion control encompassing several technologies including linear motors, linear actuators, and linear rolling guides and bearings, among others. Linear motors — an accurate option Traditional linear motors are basically a permanent magnet rotary motor rolled o...Read more -

What’s the difference between moment and torque in linear motion applications?

In linear motion, we often deal with applications that involve forces applied at a distance from a linear guide — referred to as cantilevered, or moment, loads. In these cases, we’re concerned with guide’s moment load capacity, or its ability to resist rotating. But we also deal with components ...Read more -

Smart Mechatronics Add Capabilities to Linear Motion Applications

Today’s manufacturing system OEMs and automation end users are constantly seeking technology advancements to help make their lives easier. Industry 4.0 innovations have spurred a new class of smart technologies that combine digital electronics and communication interfaces for more sophistication...Read more -

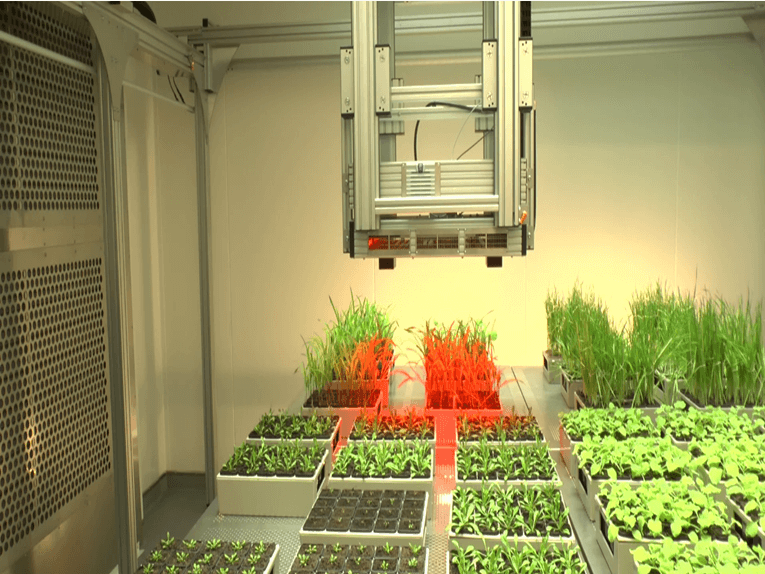

How to Make Linear Motion Systems Cleanroom Compatible

While we often talk about the importance of keeping contamination out of linear motion components such as linear guides and screws, when these systems are used in a cleanroom, the goal is just the opposite — to keep these components from introducing contamination into the environment. What exact...Read more -

What Factors Contribute to Friction in Linear Motion Systems?

Designers and engineers typically try to avoid or mitigate friction in linear motion systems. Although friction isn’t always bad — in some applications, it can provide a damping effect and help improve servo tuning — when it comes to linear motion systems, it increases the amount of force requir...Read more -

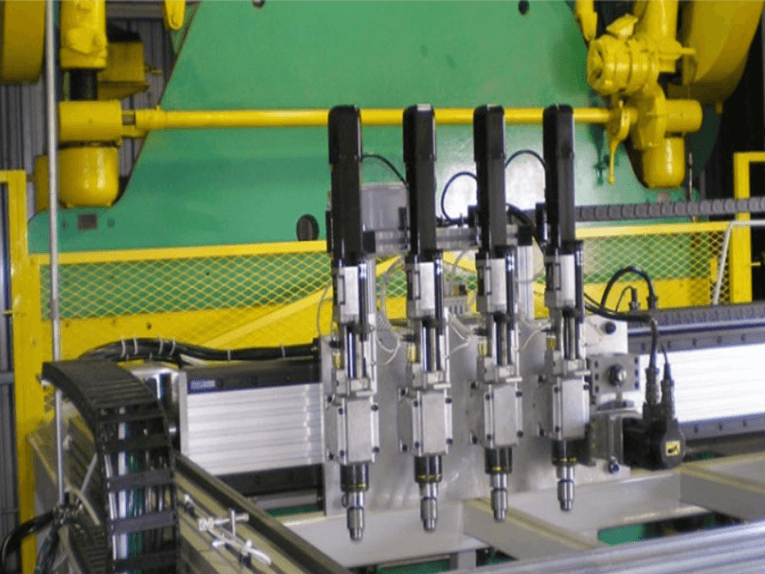

Pandemic Impacts Linear Motion Component Manufacturing and Applications

Linear motion components include everything from various types of linear actuators to linear guides, slides and ways, and a host of components in between. One thing they all have in common is that their development and production are influenced by both technological trends as well as broader mar...Read more -

Linear Motion Basics: 13 Fundamental Topics You Need to Know

Whether you’re new to designing and sizing linear motion systems, or you could just use a refresher, we’ve gathered all the articles that cover mechanical concepts used in linear motion systems and put them together here, as a sort of “linear motion basics” reference guide. Unlike our curated li...Read more -

Comparing micropositioning and nanopositioning stages

Linear stage designs can range from long-stroke, high-load gantries to micropositioning and nanopositioning stages with light payloads. Although all linear stages are designed and constructed to provide high positioning accuracy and repeatability and to minimize angular and planar errors, stages...Read more -

5 Points You Should Consider When Replace Linear Motion Systems

We outline the top five points that engineers, maintenance technicians and service providers should consider when replacing linear profile rail systems. When a linear system has reached the end of its useful life, often the easiest thing to do is to replace it with a like-for-like linear system ...Read more -

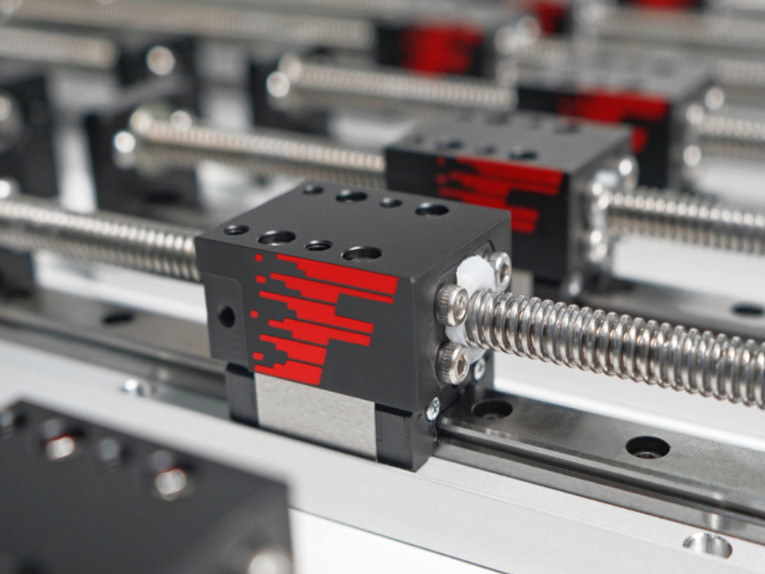

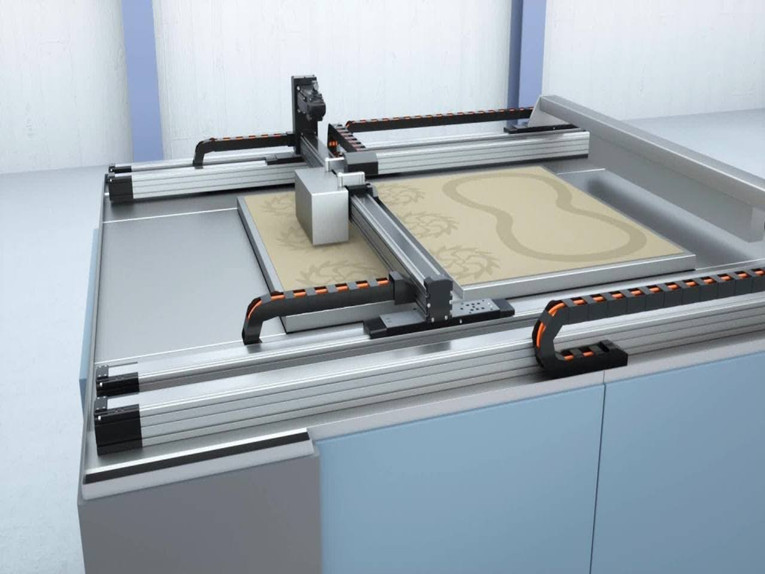

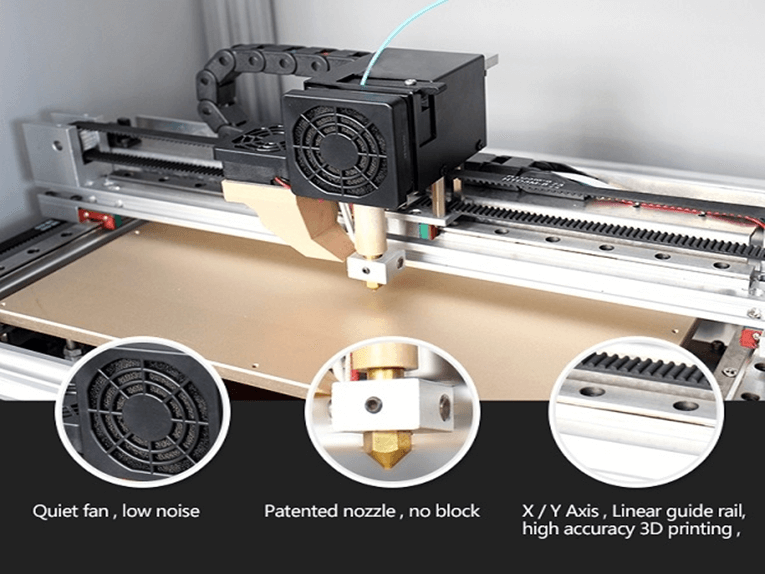

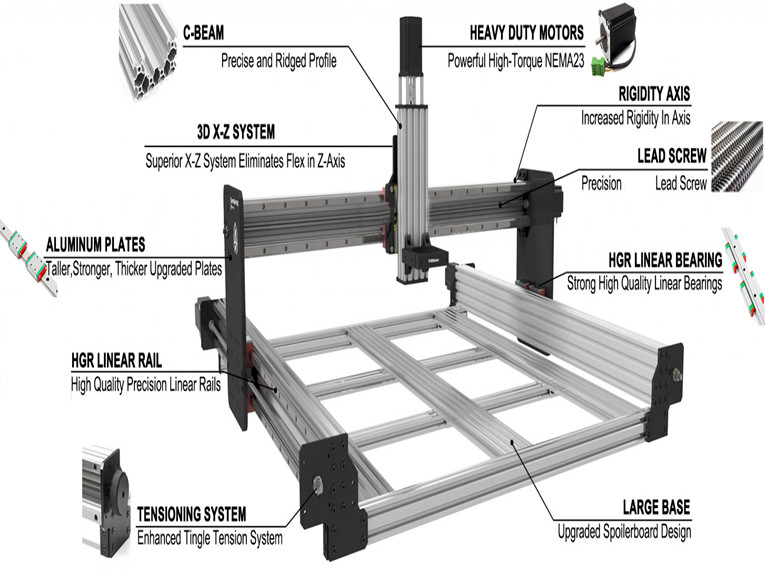

Top 5 the Most Popular Structures of Linear Rail Guide

We offer motorized stages that can be assembled into many different configurations; for example, XY stages, XYZ stages . We list top 5 the most popular stage combinations here, but you can select your own combination of family, travel and lead screw pitch in each axis to build the stage you nee...Read more