-

How to reduce jerk in linear motion systems

The most common move profiles for linear motion systems are trapezoidal and triangular. In a trapezoidal move profile, the system accelerates from zero to its maximum speed, travels at that speed for a specified time (or distance), and then decelerates to zero. Conversely, the triangular move pr...Read more -

How axial and radial loads affect linear motion systems

In any motion system, understanding the type and direction of applied and resultant loads is important for determining bearing life and analyzing deflection. In linear motion systems, we typically use Cartesian coordinates (X, Y, and Z) to define the placement and direction of loads. But for rot...Read more -

What’s the difference between backlash and hysteresis in linear systems?

In linear systems, backlash and hysteresis are often referred to as the same phenomenon. But while they both contribute to lost motion, their causes and methods of operation are different. Backlash: The enemy of linear systems Backlash is caused by clearance, or play, between mating parts, which...Read more -

The benefits and drawbacks of linear motors for dynamic applications

Linear motors can achieve high acceleration rates and long travel lengths with good thrust forces and extremely high positioning accuracies, while other drive mechanisms, such as belts, screws, or rack and pinions, must sacrifice at least one of these requirements in order to achieve the others....Read more -

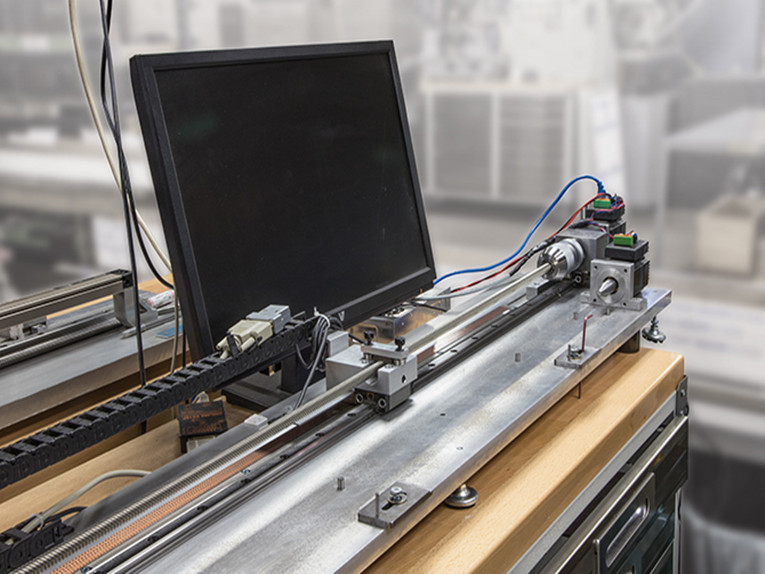

Linear Motion Systems Case Study

High-precision Z axis A manufacturer of a highly precise SLA style 3D printer needed to hold layer resolutions to an exacting level of 10 µm. The mechanical accuracy of the constant-force anti-backlash nut and leadscrew coupled with the high performance of a smart step-servo motor made for a sys...Read more -

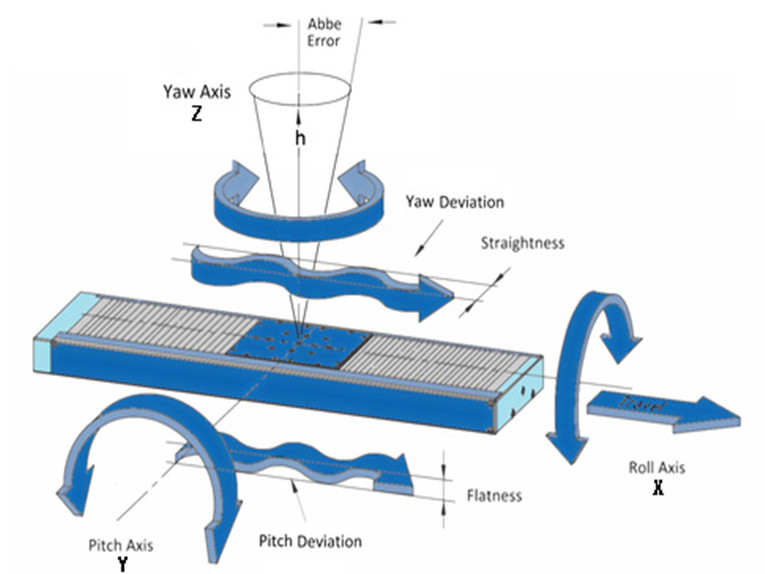

What is Abbé Error and How Does it Affect Linear Motion Systems?

When evaluating the accuracy of a linear motion system, the area of focus is often the positioning accuracy and repeatability of the drive mechanism. But there are many factors that contribute to the accuracy (or inaccuracy) of a linear system, including linear errors, angular errors, and Abbé e...Read more -

FUYU 10th Anniversary New Start New Journey 2011-2021

On January 18, 2022, Fuyu Technology celebrated its first 10th anniversary. At the meeting, Mr. Cao Zhiming, the general manager, expounded on Fuyu’s own strategy in the past 10 years. The company has agreed on the goal of “the global leader in linear modular motion systems”. I...Read more -

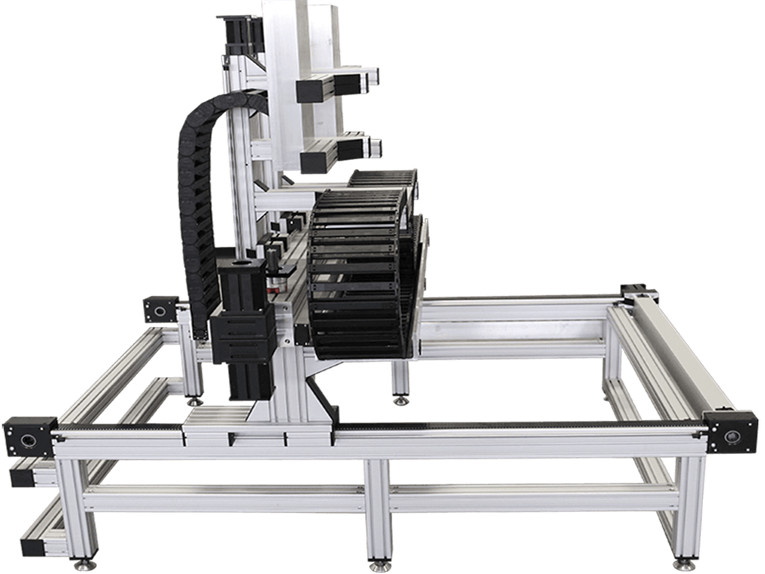

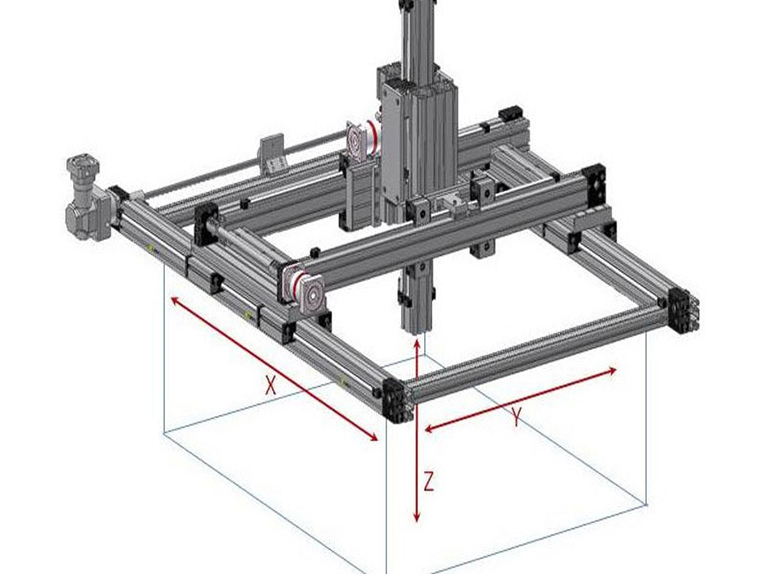

Gantry Systems: Working Outside the Envelope

Application / Industry: Packaging, production, palletizing, pick and place, automation. The Challenge: The irregular work envelopes of traditional jointed articulating arms may require redesign of existing workspaces. SCARA and articulating arm robots might be the most recognizable form of robot...Read more -

What is a split bridge system and how does it differ from a gantry?

Multi-axis linear systems come in a variety of designs, with Cartesian, gantry, and XY tables being some of the most common types. While these designs simplify construction and can provide space savings, they also introduce “stacking” errors — the compounding of errors from each axis, which mani...Read more -

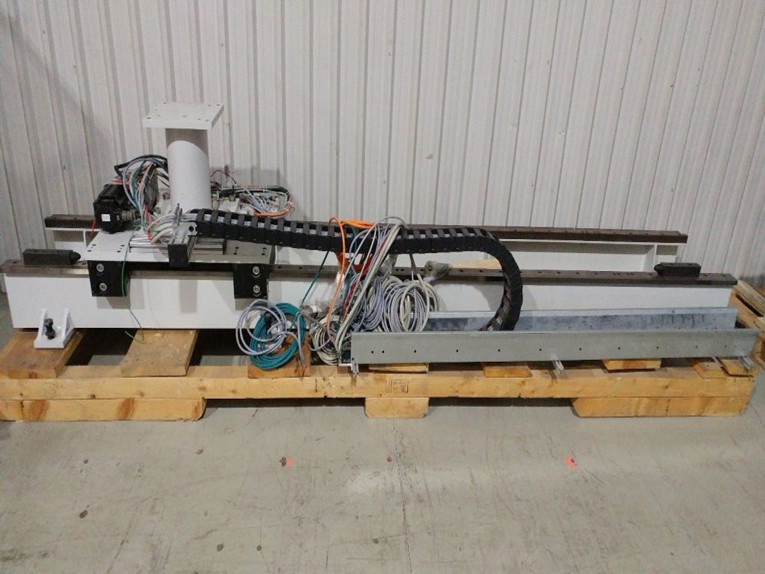

Designing linear motion tracks for robotic positioning

Robot positioning systems are long tracks in warehouse, aerospace, and automotive facilities to let one robot perform multiple tasks. Also called robot-transfer units or RTUs or 7th-axis systems, these motion designs are increasingly common for assembly, large-scale welding, and warehousing. In ...Read more -

Three easy ways to specify application requirements for linear motion systems

The first step in any automation project is to clearly define the objective — what process are you trying to accomplish or what output are you trying to produce? Once the process or output is defined, it’s time to dig into the details of the application so you can choose the right components or ...Read more -

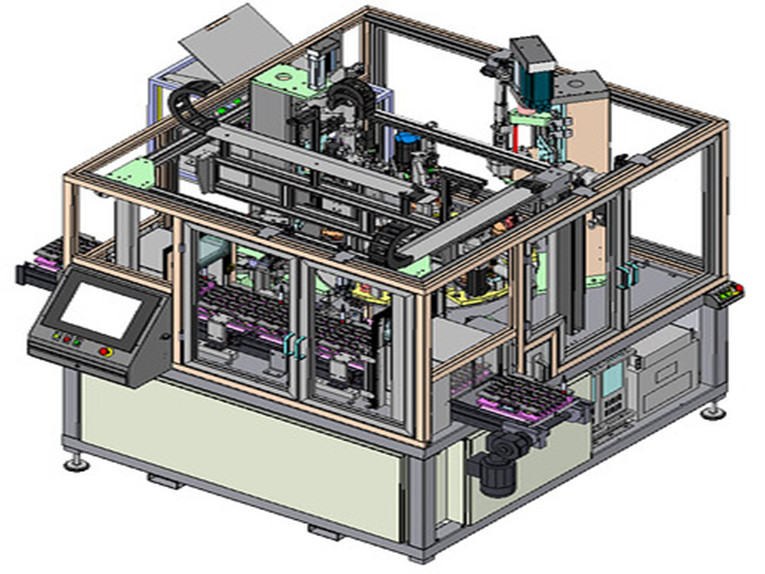

What are Cartesian Robots?

Cartesian coordinate geometry is an excellent method for mapping three-dimensional space in a simple, easy-to-understand numerical system. In the Cartesian system for three-dimensional space, there are three coordinate axes that are perpendicular to each other (orthogonal axes) and meet at the ...Read more