This XZ gantry incorporates a rack drive in the slide, eliminating the need for a separate rack. The Z axis telescopes, useful when overhead height is limited.

Which technology makes sense depends on many factors, including the operating environment, ease of installation, maintenance, and cost.

Certain cutting applications, for example, produce debris that can foul up many recirculating-ball systems and cause them to prematurely fail, particularly when they aren’t properly maintained. Guide wheels, in contrast, can be fitted with cap wipers that continuously lubricate the wheels for life and help keep debris away.

Applications with long runs can be a challenge, especially for recirculating-ball-bearing types. Installation and adjustment of such systems may take several hours because, to work properly, the guides must mount flat within tight tolerances. In contrast, wheel-type linear-motion systems, such as the FUYU Heavy Duty Series, better tolerate installations with slightly relaxed tolerances.

Heavy Duty Linear Guide uses a rigid aluminum beam to which a system of components attaches, in several different positions and in dozens of combinations. Aluminum-alloy beams have a lower overall installed cost compared with steel sections. And they are amply rigid and accurate for heavy pickand-place jobs.

Heavy Duty Series vee slides and beams come in two grades: precision ground for higher tolerances, and commercial grade for cost-sensitive applications where accuracy is not as critical. The steel slides easily fit to the aluminum beams, simplifying installation and maintenance of long runs. Slides and beams come in two standard sizes, plus a compact version. Longer runs are possible by joining individual sections. A double-edge slide gives built-in parallelism, while a singleedge model saves space.

Wheels come standard with doublerow ball bearings. Optional four-needle roller bearings handle high loads (to 100 kN) and high-accuracy applications. Linear speeds exceeding 4 m/sec are possible. Wheel-based linear guides work in any plane and are significantly quieter in operation than recirculating-ballbearing types.

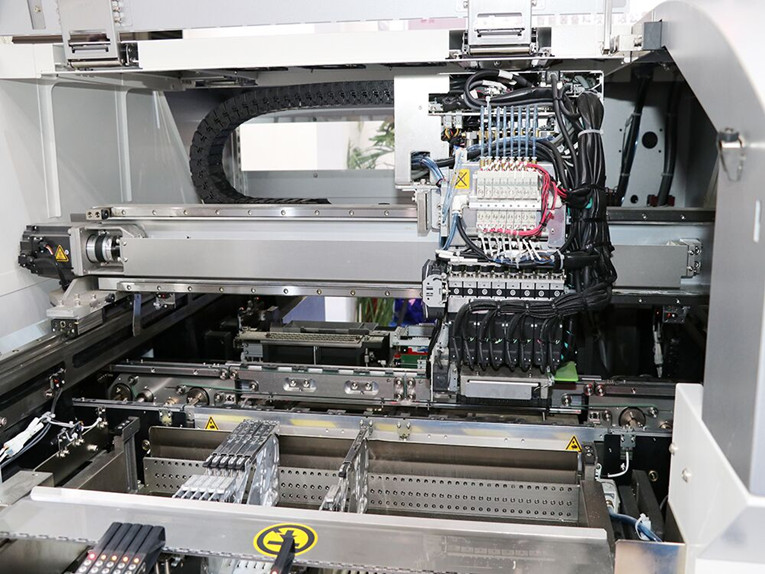

The Linear Motion Systems may incorporate a rack and pinion or belt drive. Belts run through the hollow beam, while the beam itself permits attachment of motors and pulleys. The aluminum beams can build high-load XYZ and XZ gantry systems. The Linear Positioning Systems can ship as assembled units (including drive transmissions), which lowers installation costs.

Post time: Jul-22-2021