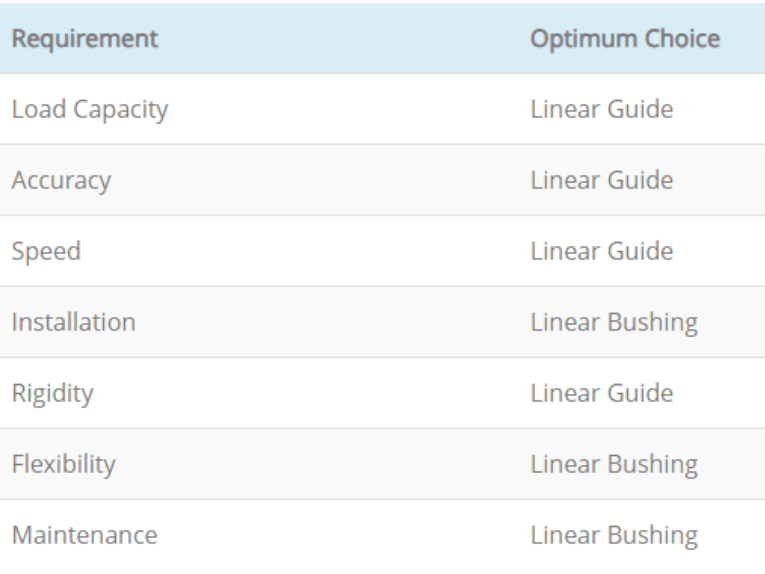

The primary difference between the two is in their load capacities. The linear bushings offer point contact between the balls and the tracks, which results in high-stress concentration. In comparison, there is contact conformity in the linear guides which considerably increases the contact area and decreases the stress concentration as shown in the figure. As a result, linear guides have higher load ratings than linear bushings.

Also, in linear guides, balls and rollers are usually arranged to provide a 45° angle of contact in all general directions of loading. Therefore, load capacity is equal in all four major planes of load application in linear guides. Conversely, the load capacity in linear bushings depends upon the direction of load application as shown in the figure.

Accuracy

In linear bearings, accuracy is defined as the variation of height over the length of travel. According to Thomson Industries, linear bushings and linear guides can achieve an accuracy of +/- 0.0008 inch and +/- 0.0001 inch respectively per 120-inch rail length. For applications requiring high accuracy, therefore, linear guides are the better choice.

Speed

Linear bushings also lose the speed race. Even the top of the line ball bushing lineup of Bosch Rexroth allows a maximum speed of 5 m/s. On the other hand, usual bail rail linear guides permit a top speed of 10 m/s.

Installation

Linear guides require a demanding installation procedure. The rails have to be supported throughout till the end. It should also be properly flattened and aligned to prevent binding, as that leads to wear and premature failure of the linear guide. Linear bearings, on the contrary, can be supported only by their ends and can tolerate unmachined surfaces and misalignments.

Rigidity

Due to supported rails throughout the span and higher contact area, the linear guides are more rigid as compared to the linear ball bearings. Thomson Industries share that linear guides are 10 times stiffer than linear ball bearings.

Additionally, the linear guides can also be preloaded up to 13% of their dynamic load to further increase their rigidity. Therefore, linear guides are better suited for applications requiring precise linear motion.

Flexibility

Linear bearings exhibit great flexibility in their operation. They can withstand both abrasive and caustic contamination. Compared to linear guides, they are more resistant to debris and can perform reasonably well in harsh environments.

Maintenance

Linear bushings are relatively maintenance-free linear bearings. They hardly require any lubrication. In comparison, linear guides do require regular lubrication.

A perk that further makes the case for linear bushings is their interchangeability between the different manufacturers. It is one of the few linear motion technology items that can be easily interchanged when required using the manufacturer’s resources.

Post time: Sep-23-2024