Many users who have purchased laser cutting machine metal only pay attention to the maintenance of the laser and the laser head of the fiber laser metal cutter. People should pay more attention to the care of the guide rail.

What is linear guide rails

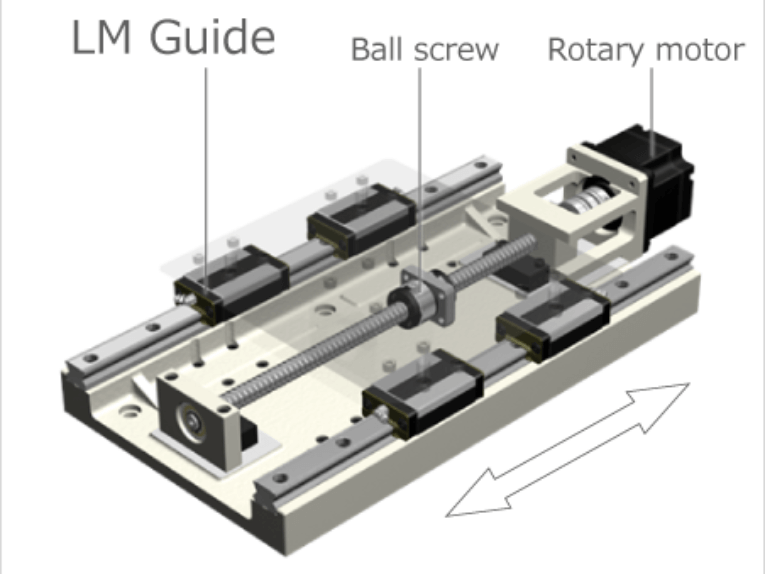

Linear guides are also called line rails, linear guide rails, and linear slide rails. They are used in linear reciprocating motion applications. They have a higher-rated load than linear bearings. At the same time, they can bear a sure torque and can achieve high Precision linear motion.

How linear rails work

The linear guide is a mechanical transmission device composed of a slider and a guide rail. Its working principle is based on the rolling contact between bearings and balls. By arranging ball bearings inside the slider and setting raceways on the guide rail, the slider can move linearly along the guide rail.

During operation, the ball bearings reduce frictional resistance through rolling contact and achieve smooth movement of the slider on the guide rail. The contact area between the balls and the raceway is small, which reduces energy loss and improves the efficiency of the system. The linear guide can also control the movement resistance and stability of the slider by adjusting the preload force to meet different work needs.

Functions of laser cutting machine linear rail guide

Plays a guiding and supporting role. In order to ensure that the machine has high processing accuracy, its guide rails and straight lines are required to have high guiding accuracy and good motion stability.

1. The guide rail is the guarantee of cutting accuracy. The linear guide rail plays a guiding and supporting role in the laser cutting machine. The smoother the movement of the guide rail, the higher the processing accuracy of the laser cutting machine.

2. The quality of the guide rail is the guarantee of the life of the equipment. The guide rail installation and adjustment of the laser cutting machine is a very important thing. The installation and adjustment of the guide rail of the cutting machine will help improve the service life and cutting accuracy of the laser cutting machine.

How to use linear guide rails

Preparation work

- Confirm that the equipment model matches the model of the guide rail to be installed;

- Ensure that the installation location is dry, flat, stable, and free of obvious vibration;

- Prepare the required installation tools and components, including screwdrivers, levels, nuts, bolts, etc.

Measure the position of the guide rail

- Determine the position and direction of the guide rail according to the equipment requirements;

- Use a spirit level and other tools to measure and confirm the horizontality and verticality of the guide rail installation position.

Installation basics

- According to the equipment requirements, install a fixed foundation or base;

- Holes for mounting bolts must be left at the bottom of the foundation;

- Ensure that the bottom of the foundation is in close and stable contact with the ground.

Installation of guide rails

- Place the guide rail in the installation position and pass the bolts through the holes;

- Use nuts to fix the guide rail on the foundation and leave a certain distance so that it can move;

- Confirm the horizontality, verticality and other parameters of the guide rail.

Adjust the position of the guide rail

- Place the laser cutting equipment on the guide rail and adjust it;

- According to the requirements of the equipment manual, adjust the position of the guide rail to make it meet the requirements;

- According to actual needs, adjust the distance between the guide rails so that each part can move freely;

- Reconfirm the horizontality, verticality and other parameters of the guide rail.

How to clean and maintain linear guides and rails

Guide rail, clean (recommended to clean once every half month, close the operation) guide rail, the linear axis is one of the core components of the equipment, and its function is to play a guiding and supporting role. , The straight line has high guiding accuracy and good movement stability.

To make the machine work normally and stably, and to ensure the processing quality of the laser cutting machine metal, the daily maintenance of the guide rail and linear axis must be done carefully.

- Step 1: Turn off the power of the fiber laser cutter

- Step 2: Remove the linear guide rail and wipe the dirt on the surface of the guide rail with a dry cloth.

- Step 3: Apply a little grease to the groove of the linear guide rail

- Step 4: Drop a few drops of lubricating oil on the linear guide rail, and reciprocate the linear guide rail several times to ensure that lubricating oil is everywhere on the guide rail.

- Step 5: Install the linear guide rail. Then turn on the main power of the sheet metal laser cutting equipment and press the switch of the CNC laser cutter for metal.

Regular maintenance of fibre laser

- The power cord of the fiber laser should be checked frequently, and the shell of the equipment should be connected to the ground.

- Before the laser works, it is necessary to monitor whether the voltage signal meets the requirements of the manual.

- The daily protection of the optical fibre and the optical fibre head must be in place and cannot be bent. It is a consumable item.

- The fiber optic head lens is protected from dust. When cleaning the dust, use a cotton swab dipped in 99.99% pure ethanol.

Post time: Oct-21-2024