Industries That Use Pick and Place Robots

Pick and place robots are used in a variety of areas as industrial robots. Some of the industries that utilize these robots are:

Packaging:

Packaging is one of the most common types of applications of pick and place robots. From food packaging in a packaging container to palletizing robots, pick and place robots have a vast use in food processing industry.

Delivery:

Pick and place robots have found their application as delivery robots as well in several high-tech environments around the world.

Research:

These robots are also used for research purposes when handling highly sensitive elements and compounds in a scientific environment.

Electronics:

Pick and place robots place incoming components on circuit boards of electronics like phones, TV, computers, etc. are brought and assembled together by pick and place robots for fast assembly processes.

Palletizing robots:

Pick and place robots are used in some form in almost every industry as palletizing robots, for placing items one on top of another to make stacks (called Pallets) of items.

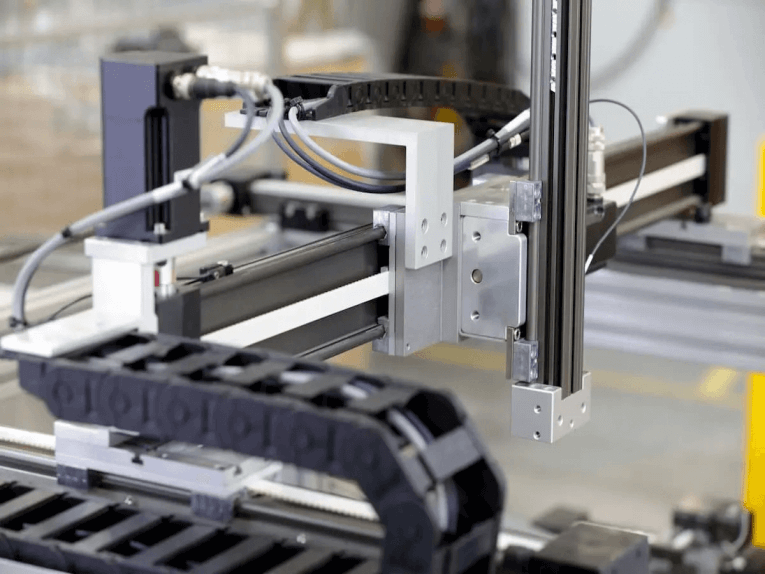

4 Key Factors to Choose the Right Pick and Place Robots for Your Business

When it comes to getting a pick and place robot for your production line, you cannot simply go ahead and get the first one you see. It requires careful research, based on some important factors. These factors are:

Axes:

The number of axes determines the directions in which the robot is capable of moving. A five-axis robot can pick and place an object to any location within the same plane, while a six-axis robot can transfer objects to different planes as well. Additional axes can create twisting and turning motions for different orientation of the object.

Reach:

The reach is the entire work envelope that the robot can reach. The robotic work envelope will be defined by the spread of your workplace. A larger, spread out workspace will require a robot with a larger reach. For a smaller workspace, a smaller reach is sufficient.

Speed:

For high volume applications, you will require a high speed pick and place robot. If your volume requirement is not that high, you speed of movement is something you can compromise.

Repeatability:

Repeatability is the robot’s ability to pick and place items to the exact particular location. High repeatability means better positioning accuracy, and is a desired quality for a smoother operation.

How Much Do Pick and Place Robots Cost?

Pick and place robots are not just one robotic machine, but a properly integrated system consisting of conveyor belt, advanced vision systems, and more. The entire setup is cheaper than you might spend on labor, and costs somewhere between $40,000 to $50,000.

Simple pick and place robots that do not require high-tech facilities such as advanced vision technologies can come at just a few thousand dollars.

If you compare these numbers with what you spend on the human workforce and related expenses, you will find that the human counterpart costs twice or thrice as much, making pick and place robots a significantly cheaper and more efficient investment.

Conclusion

In this day and age where the manufacturing process happens on a production line to meet peak demand periods, handpicking items is no longer an option.

Any area that slows up production is just another bottleneck in the manufacturing process.

This is why, pick and place robots are not just an option but a necessity in this environment. This is especially true for the food packaging industry, where there are added factors at play such as contamination by humans or preserving food integrity.

Post time: May-04-2023