Robot laser cutting overcomes many of the disadvantages of conventional laser cutting machines.

Here are a few benefits of using robot laser cutting:

1. Robots are suitable for any cutting path — You are no longer restricted to cutting in only one plane, as with conventional machines. A robot can position the laser cutting head in almost any position and orientation within its workspace.

2. Robots are extremely flexible — Which means that you only need to use one robot when you might have to use multiple conventional laser cutting machines.

3. Large workspaces — Many industrial robots also have large workspaces which means you don’t sacrifice the large workspace you’d expect from a conventional machine.

4. They take up less floor space — Even with their large workspaces, robots can end up using less of your floor space, especially when you consider that you only need one robot instead of multiple machines.

5. They can run autonomously — When programmed correctly, a robot will be able to run completely autonomously. Moreover, they can take over tasks like depalletizing and material handling, which reduces human intervention to a minimum.

Robot Laser Cutting: A More Flexible Approach

How can you overcome these disadvantages of conventional laser cutting?

How can you improve the flexibility of your cutting process while reducing the amount of floor space used by laser cutting machines?

Robot laser cutting is a relatively new manufacturing operation. Thanks to the continued advancement of robotic technology, it is now easier than ever to take advantage of this application.

You might think that lasers and robots are a strange pairing. However, lasers are an increasingly common end effector for robots. The agricultural industry even has robotic weedkillers that use lasers instead of pesticides.

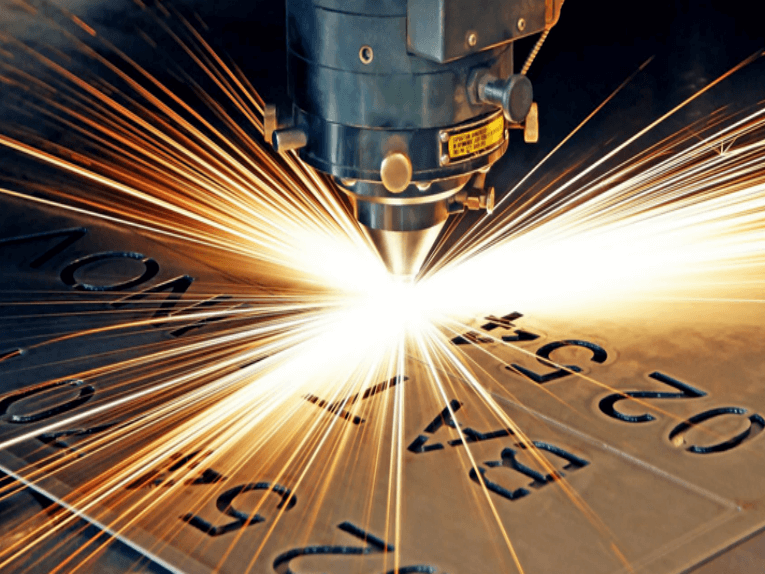

How robot laser cutting works

Laser-cutting robots are pretty simple.

You add a laser end effector to the end of the robotic arm. Then, just like the cutting head in a conventional laser cutting machine, the robot positions the laser where it needs to be to carry out your cutting task.

Programming Your Robotic Laser Cutting Machine

The key to getting the most from your laser cutting robot is to combine the hardware with a good programming system.

This ensures that you can quickly program complex paths into the robot even if you don’t have extensive programming experience.

The specifics of programming a laser-cutting robot will depend on the type of task you need to perform. If you use the robot to etch an image on the surface of the material, it will be similar to programming a drawing task. If you are using the robot for cutting, the task is slightly different.

Post time: Feb-20-2023