Precision industrial motion systems are used in test, assembly or laser micro-machining of high precision and high value components and in electronics, optics, and photonics manufacturing, to name a few. Considering that every modern automobile sold in the US has at least one camera on board and that high end models are equipped with a multitude of sensors, based on vision, ultrasound, Radar or even Lidar, the need for high-speed and high precision motion and positioning equipment in industrial automation is growing.

Many of these sensors require micron or sub-micron precision during assembly and/or test and the linear and rotary motion modules used must be robust for 24/7 operation, providing dynamic performance (acceleration, quick step and settle with minimum overshoot and settling time) to achieve the high throughput demand. Flexible network protocols, such as Ethercat which allows for real-time multi-axis synchronized motion and the capability of synchronizing with external events, are a plus when it comes to integrating the precision positioning equipment with lasers, machine vision, dispensers, etc.

The high dynamics and low maintenance requirements are met by linear motors – low inertia, no friction, no wear. High resolution and accuracy is provided by a wide range of linear encoder options – absolute encoders, for example, save time and add functional safety because they render homing procedures obsolete and avoid run-away situations caused by incremental encoder signal transmission issues. Modern linear encoders can measure motion in increments smaller than one nanometer.

For high force applications, ball-screws with robust servo motors and the ability to run directly on 110/240 volts AC servo drives are available. The ability for the end user to lubricate the ball screw rails without dismantling the stages is a great advantage.

Machine builders in the laser industry also need such positioning stages to offer good resistance to debris ingress and tolerance to hot particulates, so the linear stages have side sealing strips, air purge connections, and hard covers. As the size and mass of the manufactured parts may be challenging, the system components used need to be highly precise, stiff, robust, and offer reliable performance. Industrial motor connectors which are easy to handle and adjust, standard high flex cables, and the ability for the end user to lubricate the ball screw without dismantling the stages and other features often requested.

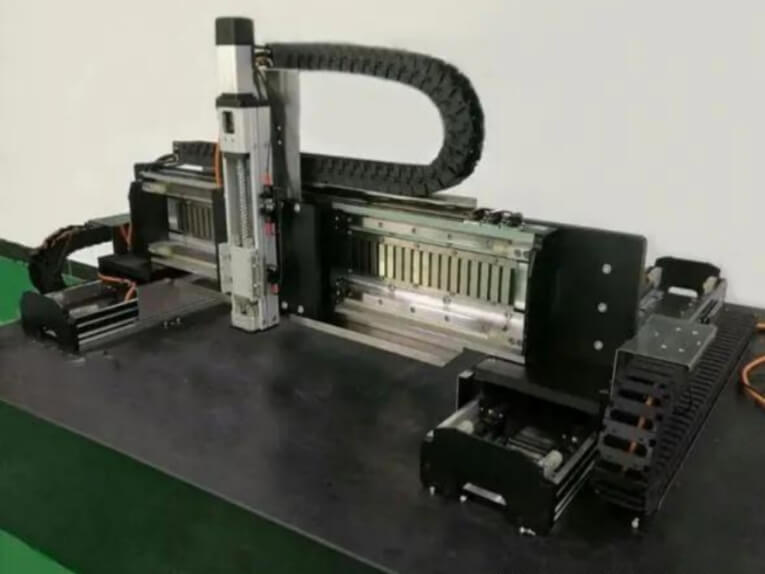

Design engineers who require ease of installation appreciate the machined reference edge on the new generation of linear stages for easy placement and alignment on their machine base. Standard cable management options and flexible motor cable exits are further advantages. Other important requirements for the linear stage manufacturer are the capability to provide metrology data, error correction mapping or aligned XY or XYZ multi-axis combinations.

Post time: Sep-06-2023