WHAT ARE GANTRY ROBOTS?

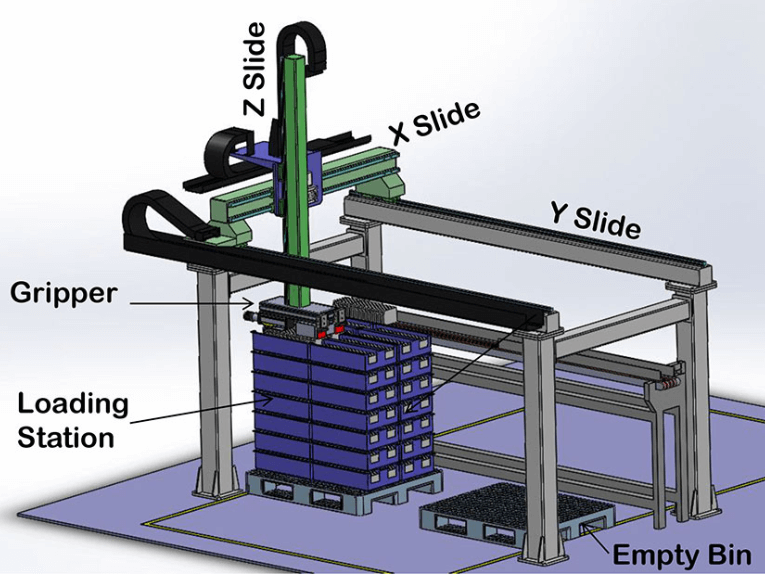

A Gantry Robot is an automated industrial system that can also be referred to as a Cartesian Robot or a Linear Robot. Gantry robots typically move in linear paths creating a three dimensional cubic envelope of space it can work within.

For this reason, the term Cartesian robot is ideal since the overall top-down working space is bound by two linear paths that intersect at right angles to create the working plane (typically referred to as X and Y.) When you add a third axis (typically referred to as Z), this creates the depth at which the end-of-arm-tool can operate inside the cubical envelope. While these three axes are the principle forms of movement, gantry robots may contain as few or as many axes as necessary to perform the required task.

A common option is to add a fourth rotational axis, “U”, to the bottom of the Z beam. This axis rotates the end of arm tool such that the tool stays parallel with the floor. Options exist to rotate the tool in a vertical fashion rather than horizontal.

Sage Gantry Robots use various way systems and mechanical drives. Way systems include wheel & track, profile rail, and wheel & beam. Drive methods include belt, wire rope, tractor, chain, and closed loop friction.

In rare cases, gantry robots are mistakenly referred to as Smart Cranes since they resemble industrial overhead cranes. Gantry robots are not defined as cranes but they do share visual similarities and core concepts. Cranes typically have unsupported z-axis cable or wire rope systems whereas gantry robots offer a rigid mechanical z-axis solution with little deflection and high repeatability. Overhead cranes are manually operated so the term “smart” applies to gantry robots being fully autonomous without the need for operator input.

In being autonomous, gantry robots operate independently of human beings in their workcell and offer precision and accuracy not available to overhead cranes.

WHEN SHOULD YOU USE A GANTRY ROBOT?

Any type of robot can be used when automating tasks demanding high repeatability. Industrial automation can optimize production, reduce injuries, and allow for employees to focus on other tasks such as quality control. Specifically, a gantry robot is ideal when a large or heavy object needs to be manipulated and handled with precision or the task requires the object to be manipulated over a large area.

Sage Gantry Robots are designed in a wide range of sizes, strengths, and configurations. A small gantry robot is similar in size to that of a small room, whereas a large gantry robot would be as long as a football field and as wide as fifty feet or more, depending on end-user facility constraints. Payloads can vary from just a few pounds to several tons.

Gantry Robots are used mostly in pick and place applications but have been implemented in a variety of tasks including:

PALLETIZING • DEPALLETIZING • MACHINE LOADING/UNLOADING • IN PROCESS • END OF LINE • MATERIAL HANDLING • MACHINE TENDING • SORTATION AND STORAGE • PACKAGING

COMMON GANTRY ROBOT APPLICATIONS

Multi-Line Palletizing is one of the most common tasks requiring automation.

Fundamentally, these types of systems build pallet loads of individual product types for multiple product production lines simultaneously that are ready to ship to end users or distribution facilities. Products are transported to the robot either by individual conveyors dedicated to respective products, or by trunk lines delivering a multitude of products. When multi-product trunk lines are used, a sortation conveyor diverts individual products to pre-determined lanes for palletization. The robot receives product information for each lane and builds the appropriate stack patterns for each product.

Gantry robots are one of the best solutions for multi-line palletizing situations. Multiple load building locations and product infeed lanes take up floor space and require a robot with a suitable working envelope to reach all infeed lines and build locations. A gantry robot provides enough travel to serve numerous production lines with only one robotic head. In contrast, a fixed-mount articulated arm’s limited range prevents it from palletizing more than a few adjacent production lines. However, some solutions employ an articulated arm placed on a rail or other mobile platform. In those cases, the articulated arm has effectively become the end-of-arm tool of a gantry robot. Due to their fully customizable working footprint, and mechanical simplicity, gantry robots represent an ideal fit for multi-line palletizing scenarios.

Automated Storage and Retrieval Systems are common manufacturing mid-stream applications for gantry robots.

The envelope inside of a gantry is used not only as a staging location but for actual temporary storage and accumulation. Variations in production and demand determine storage duration for each type of product within the envelope. ASRS gantry robots optimize floor space and warehouse storage while maintaining direct access to those products.

Database systems track the lifespan of storage locations enabling the potential for FIFO (First In, First Out) product flow. This allows the ability to discharge outdated SKUs or make room for more common SKUs. In addition, identical products can be grouped together into single picks or into adjacent locations maximizing throughput and organization.

For operations involving large or heavy products limiting the usefulness of a rack system, gantry robot ASRS systems offer a flexible alternative.

Post time: Jul-29-2024