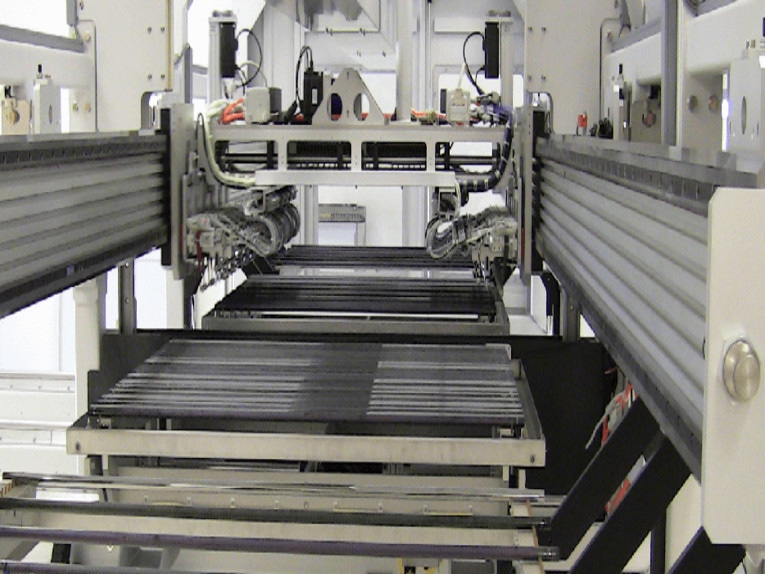

Typical Configuration of Motion System Design

Linear motion is central to many moving machines, and the direct-drive nature of linear motors can simplify overall machine design in these applications. Other benefits include improved stiffness, because linear motors are fixed directly to the load.

Integrating these motors (and the peripheral components they require) can seem daunting, but the process can be broken down into five simple steps. Following this step-by-step process allows machine and robot builders to reap linear-motor benefits without extraneous effort or complexity.

1. Determine motor type: Iron core versus ironless

The first step is to select the linear motor from the types available.

Iron-core motors: Iron-core motors are most common, and suitable for general automation applications. Iron-core refers to this motor’s coil construction, which consists of iron-core laminations. A typical configuration consists of a single-sided stationary magnet track and a moving motor coil or forcer. The iron core maximizes the generated thrust force, and creates a magnetic attraction force between the coil and magnets.

This magnetic attraction force can be used to effectively increase the rigidity of the linear guidance system by preloading the linear motion bearings. Magnetic preloading can also boost the system’s frequency response by improving deceleration and settling.

On the other hand, the attraction force must be properly supported by increased load capacity from supporting members and linear bearings. This may degrade the machine’s mechanical design freedom.

A second iron-core linear-motor configuration consists of a pair of stationary magnet tracks placed on either side of the moving coil. This patented construction negates the effects of magnetic attraction while delivering highest force per cross-sectional area. The balanced design reduces bearing load, allowing use of smaller linear motion bearings and decreasing bearing noise.

Motionsystemdesign Com Motors Drives 0111 AdvantagesIronless motors: Ironless linear motors also exist; these motors have no iron in their coils, so there’s no attraction between the motor members.

The most common ironless type is the U channel: Two magnetic tracks are joined to form a channel in which the motor coil (or forcer) moves. This motor is ideal for applications requiring low velocity ripple and high acceleration. The zero-attraction force and zero-cogging nature of the ironless construction minimizes torque ripple; acceleration is increased because the coil is relatively lightweight.

A second ironless configuration is in the form of a cylinder. Magnets are stacked inside a stainless steel tube, and the motor coil moves around the cylinder. This configuration is suitable when replacing ballscrews, as it produces much higher speeds and positioning accuracy in roughly the same envelope.

Coil sizing and track length

No matter the configuration, all linear-motor coils should be sized to application requirements: applied load, target move profile, duty cycle, accuracy, precision, service life, and operating environment. Tip: Enlist technical support from linear-motor manufacturers and sizing software (which is often free) to select the best motor type and size for a particular application.

Magnet track sections are offered in several lengths and can be stacked end-to-end to achieve the target travel length, with the total magnet length being virtually limitless. To simplify design and reduce costs, it’s best to use the longest length magnet track sections available from the manufacturer.

2. Decide on an encoder

The second step when designing a linear motor system is selection of the linear encoder. The most common are incremental linear encoders with optical or magnetic read head sensors. Select an encoder with the required resolution and accuracy for the application, and one that is suitable for the machine environment.

Encoder feedback is typically sent back to the servo amplifier via either a sinusoidal analog or a digital pulse train. Another option is high-speed serial encoder feedback — providing higher data rates, higher bit resolution, greater noise immunity, longer cable lengths and comprehensive alarm information.

Serial communications connect in two ways.

Direct communication between the amplifier and encoder is possible with encoders featuring a serial encoder protocol compatible with the amplifier.

Where an encoder has no serial output (or where the serial output protocol is incompatible with amplifier) a serial converter module can be used. In this case, the module accepts an analog signal from the encoder along with the Hall sensor signal, subdivides the analog signal, and transmits this signal data serially to the servo amplifier. Hall sensor data is used at powerup and to verify encoder feedback.

Several linear encoder manufacturers now offer absolute linear encoders that support a variety of serial communication protocols, including proprietary protocols from third-party amplifier manufacturers.

3. Pick the amplifier

The third step in the design process is selection of the servo amplifier. The amplifier must be correctly sized based on the motor.

Plug and play is a feature that can only be offered by suppliers that make both servomotors and amplifiers. Some suppliers provide plug and play to reduce startup time and ensure proper configuration.

Some servo amplifiers feature automatic motor recognition and a tuning-less mode, which eliminate the need to tune the servo system. With this software, motor specifications (including overload characteristics) are automatically uploaded to the servo amplifier from the motor at powerup. This removes potential user error when inputting motor specifications, virtually eliminating the risk for motor runaways and phasing errors.

4. Select support members and bearings

The two final design steps go hand-in-hand to complete the linear motor system design: The fourth step is to select a linear motion bearing system, and the fifth is to design the support members.

There are two important alignments in most linear motor assemblies: the motor-to-magnet gap distance between the coil and the magnet track, and the gap distance between the encoder read head and linear scale. The latter criterion is eliminated when selecting an enclosed linear encoder.

Tips:

The linear motion bearings should provide sufficient precision to meet the gap tolerances, while the support members should be designed to properly space the components and meet the parallelism requirements of the linear bearings and encoder.

Once these criteria are met, the selection and design of the bearings and supporting members ultimately depends on the machine’s performance requirements. Applications requiring high accuracy and precision need a high resolution and high accuracy encoder, plus high-accuracy linear bearings.

When sizing these bearings, account for the payload and the magnetic attractive forces associated with iron-core linear motors. In many cases, the supporting members of the linear bearings and magnet tracks can be integral to the machine frame.

Post time: Mar-02-2020