The demand for quality electronics has increased significantly due to everyday devices’ growing complexity and connectivity. This puts pressure on manufacturers to produce more products more competitively. Automation is the primary way manufacturers achieve these productivity increases.

The Basics of Electronics Manufacturing Robots

Many robot types are capable of being electronics manufacturing robots, depending on the context of the application. They are deployed in several industries that implement electronic devices in their products:

1. Consumer electronics

2. Commercial/industrial electronics

3. Automotive

4. Aerospace

5. Medical device manufacturing

Electronics Manufacturing Robot Applications

There are a few critical tasks that robots handle in electronics manufacturing. These tasks are repetitive, simple, and high-volume. Common applications include:

1. Assembly

2. Soldering

3. Testing

4. Inspection

5. Packaging

Assembly

Assembly is the basic process of building up products out of smaller sub-components. This often includes mounting components like diodes, capacitors, and transistors. It can also include securing a finished PCB in its housing within the larger product.

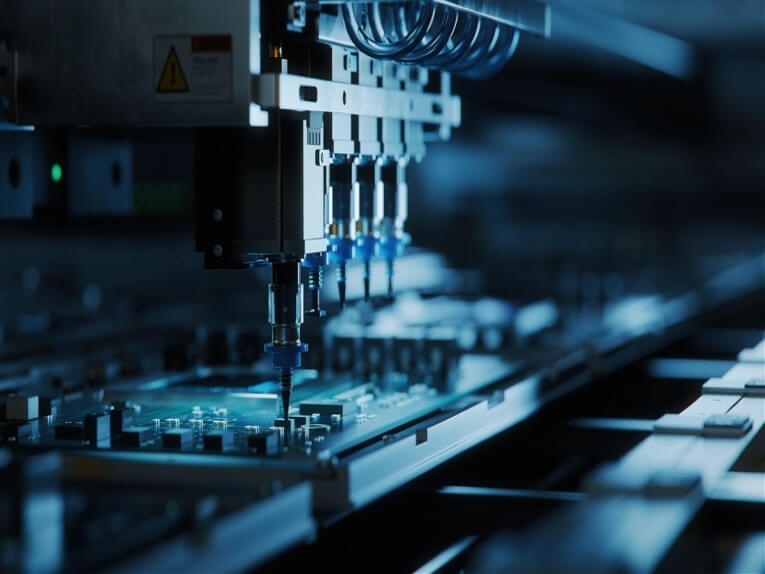

Soldering

The soldering process describes welding electronic components to a board to complete an electrical circuit. Soldering is a standardized automation task, meaning it is a common task with tried and true solutions. Manufacturers often assemble PCB components as part of their production process. This task includes soldering subcomponents onto the board. Manufacturers and integrators have been automating the soldering task for decades. Due to this experience, automated soldering is well-understood. There is broad market support for soldering solutions. Keep in mind, you must manage repeatable part presentation and tool head selection with your automated soldering project.

Testing

Testing is required to ensure that the production of electronics is of the highest quality, helping catch defects before the electronics are shipped out. Testing is typically a manual process, but robots have taken on more testing applications such as continuity testing and sending signals to the board to determine if it’s functioning correctly.

Inspection

Inspection, similar to testing, is a task that has been historically handled manually by manual laborers. However, introducing reliable and affordable machine vision systems has allowed robots to handle inspection tasks. Pairing a robot with machine vision can allow defects to be handled in real-time.

Packaging

The packaging process is critical to most industries. Electronics manufacturing is no exception. The high-volume production environment makes the packaging step one that is sensitive to bottlenecking. Automation is a standard solution for increasing the throughput of the packaging process. Key considerations include part presentation and choosing the correct end-of-arm tooling for the product.

Post time: Mar-10-2023