Cartesian Robot’s Load

The load capacity of a robot (as specified by the manufacturer’s ) required to be greater than the total payload’s weight at the end of the robotic arm with tooling parts. SCARA and six-axis robots are constrained because they carry loads on extended components.

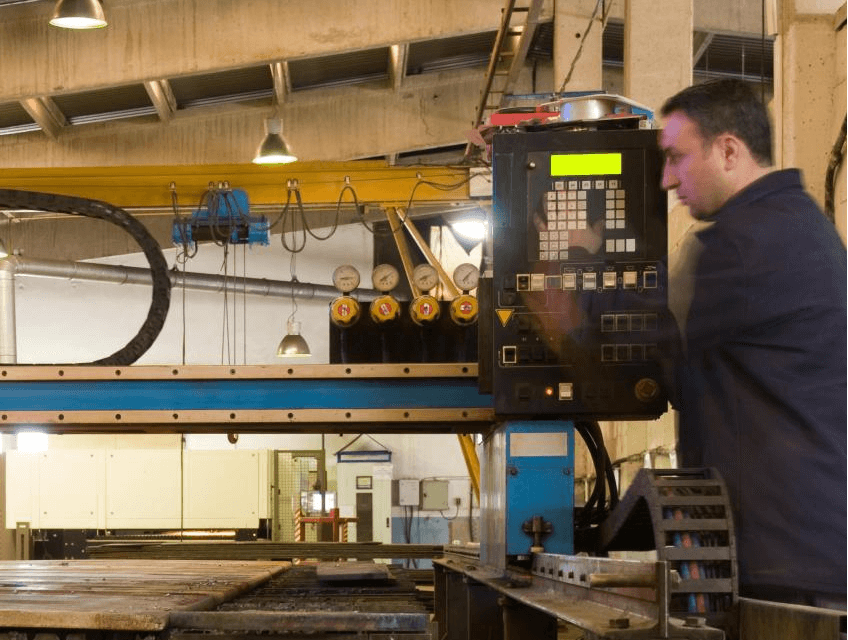

For example, a machining center that manufactures bearing assemblies weighing 100 kg or more. Except for the largest SCARA or six-axis robots, the payload exceeds their capabilities. A traditional Cartesian-robot, on the other hand, can easily pick and position those loads because its support frame and bearings support the whole range of motion.

Cartesian Robot’s Orientation

The robot’s direction is determined by how it is positioned and how it places the pieces or items being pushed. If the floor or line-mounted pedestal of a SCARA or six-axis robot causes an obstacle, such robots may not be the right choice. Small-frame Cartesian robots may be placed overhead and out of the way if the application only involves rotation in a few axes.

However, for complex component handling or function involving four or more axes of motion, a Cartesian robot’s structure may be too obstructive, and a compact SCARA robot, which may be as small as 200 mm2 and four bolts on a pedestal, maybe a better fit.

Cartesian Robot’s Speed

Robot-manufacturer catalogs also have speed ratings in addition to load ratings. Acceleration times over long distances are critical to remember when picking robots for pick-and-place applications. Cartesian-robots can reach five m/sec or higher speeds, rivaling SCARA and six-axis robots.

Cartesian Robot’s Duty Cycle

This is the time it takes to complete a single operating loop. Robots that constantly run 24 hours a day, seven days a week (as in high-throughput scanning and pharmaceutical manufacturing) hit the end of their useful lives faster than those that run for eight hours five days a week. To stop potential aggravation, fix these problems ahead of time and buy robots with long lubrication periods and low maintenance requirements.

Post time: Dec-20-2022