Robots, drones, and sensors help with inspections now and could be fully automated in the not-too-distant future.

Drones and crawling robots outfitted with special scanners could help wind blades stay in service longer, which could lower the cost of wind energy at a time when blades are getting bigger, pricier, and harder to transport. To that end researchers at DoE’s Blade Reliability Collaborative and Sandia National Laboratory have been working on ways to noninvasively inspect wind blades for hidden damage while being faster and more detailed than traditional human inspections with cameras.

Wind blades are the largest single-piece composite structures built in the world, even bigger than any airplane, and they often get put on machines in remote locations. A blade is subject to lightning, hail, rain, humidity, and other forces while running through a billion load cycles during its lifetime, but you can’t just land it in a hanger for maintenance.

Routine inspection and repair, though, is critical to keeping turbine blades in service, Paquette says. However, current inspection methods don’t always catch damage soon enough. Sandia is drawing on expertise from avionics and robotics research to change that. By catching damage before it becomes visible, smaller and cheaper repairs can fix the blade and extend its service life, he says.

In one project, Sandia outfitted a crawling robot with a scanner that searches for damage inside wind blades. In a second series of projects, Sandia paired drones with sensors that use the heat from sunlight to detect damage.

Traditionally, the wind industry has had two main approaches to inspecting wind blades, Paquette says. The first option is to send someone out with a camera and telephoto lens. The inspector moves from blade to blade snapping photos and looking for visible damage, such as cracks and erosion. The second option is similar, but instead of standing on the ground the inspector rappels down a wind blade tower or maneuvers a platform on a crane up and down the blade.

In these visual inspections, you only see surface damage. Often though, by the time you can see a crack on the outside of a blade, the damage is already quite severe. You’re looking at an expensive repair or you might even have to replace the blade.

These inspections have been popular because they are affordable, but they cannot catch damage before it grows into a larger problem, Paquette says. Sandia’s crawling robots and drones are aimed at making noninvasive internal inspection of wind blades a viable option for the industry.

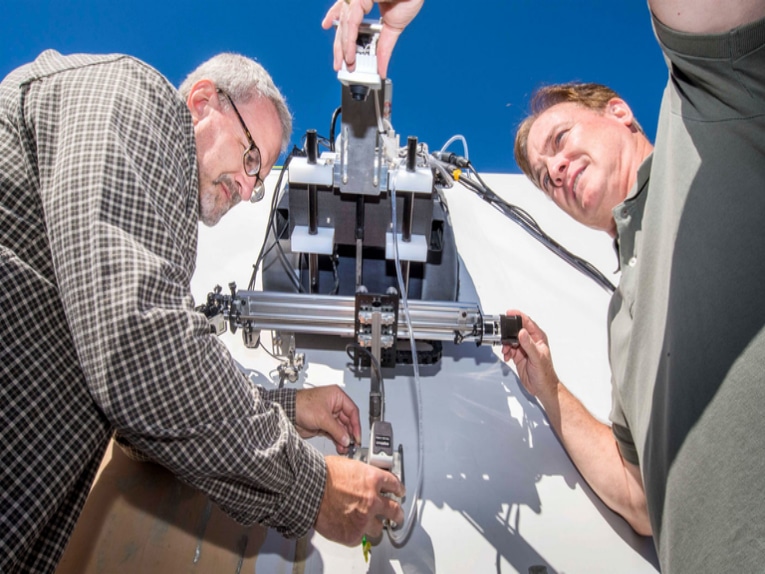

Sandia and partners International Climbing Machines and Dophitech built a crawling robot inspired by the machines that inspect dams. The robot can move from side-to-side and up and down a wind blade, like someone painting a billboard. On-board cameras snap high-fidelity images to detect surface damage, as well as small demarcations that may signal larger, subsurface damage. While moving, the robot also uses a wand to scan the blade for damage using phased array ultrasonic imaging.

The scanner works much like ultrasound machines used by doctors to see inside bodies, except in this case it detects internal damage to blades. Changes in these ultrasonic signatures are automatically analyzed to indicate damage.

Sandia senior scientist and robotic crawler project lead Dennis Roach says that a phased array ultrasonic inspection can detect damage at any layer inside the thick, composite blades.

Impact or overstress from turbulence creates subsurface damage that is not visible. The idea is to find damage before it grows to critical size and can be fixed with less expensive repairs that also decrease blade downtime. We want to avoid any failures or the need to remove a blade.

Roach envisions the robotic crawlers as part of a one-stop inspection and repair method for wind blades.

Picture a repair team on a platform going up a wind blade with the robot crawling ahead. When the robot finds something, inspectors can have the robot mark the spot so the location of subsurface damage is evident. The repair team grinds away the damage and repairs the composite material. This one-stop shopping of inspection and repair lets the blade be back in service quickly.

Sandia also worked with several small businesses in a series of projects to outfit drones with infrared cameras that use the heat from sunlight to detect hidden wind blade damage. This method, called thermography, detects damage up to a half-inch deep inside the blade.

We developed a method that heats the blade in the sun, and then rolls or pitches blade until it is in the shade. Sunlight diffuses into the blade and equalizes. As that heat diffuses, you expect the surface of the blade to cool. But flaws tend to disrupt the heat flow, leaving the surface above and flaws hot. The infrared camera detects those hot spots and labels it as detected damage.

There are ground-based thermography devices currently used for other industries, such as aircraft maintenance. Because the cameras are mounted on drones for this application, concessions have to be made, Ely says.

You don’t want something expensive on a drone that could crash, and you don’t want a power hog. So, we use really small IR cameras that fit our criteria and then we use optical images and lidar to provide additional information.

Lidar, which is like radar but uses visible light instead of radio frequency waves, measures how long it takes light to travel to and from a point to determine the distance between objects. Taking inspiration from NASA’s Mars lander program, the researchers used a lidar sensor and took advantage of drone movement to gather super-resolution images. A drone inspecting a wind blade moves while it takes images, and that movement makes it possible to gather super-resolution images.

You use the movement to fill in additional pixels. If you have a 100- by 100-pixel camera or lidar and take one picture, that resolution is all you’ll have. But if you move around while taking pictures, by a sub-pixel amount, you can fill in those gaps and create a finer mesh. The data from several frames can be pieced together for a super-resolution image.

Using lidar and super-resolution imaging also lets researchers precisely track where the blade is damaged, and lidar can also measure erosion on blade edges.

Autonomous inspections of bridges and power lines are already realities, and Paquette believes they also will become important parts of ensuring wind blade reliability.

Autonomous inspection is going to be a huge area, and it really makes sense in the wind industry, given the size and location of the blades.Instead of a person needing to walk or drive from blade to blade to look for damage, imagine if inspections were automated.

Paquette says there is room for a variety of inspection methods, from simple ground-based camera inspections to drones and crawlers working together to determine the health of a blade.

I can envision each wind plant having a drone or a fleet of drones that take off every day, fly around the wind turbines, do all of their inspections, and then come back and upload their data. Then the wind plant operator will come in and look through the data, which will already have been read by artificial intelligence that looks for differences in the blades from previous inspections and notes potential issues. The operator will then deploy a robotic crawler on the blade with suspected damage to get a more detailed look and plan repairs. It would be a significant advance for the industry.

Post time: Mar-08-2021