Cartesian robots are a very common and simple robotic technology that manufacturers have used for decades. Across industries and applications, companies are reaping the rewards of this scalable technology. But what exactly are these robots? For which tasks can they be used? How do you know if it’s right for you? This article will discuss these topics and more to help you understand if this robot is right for you.

What Is a Cartesian Robot?

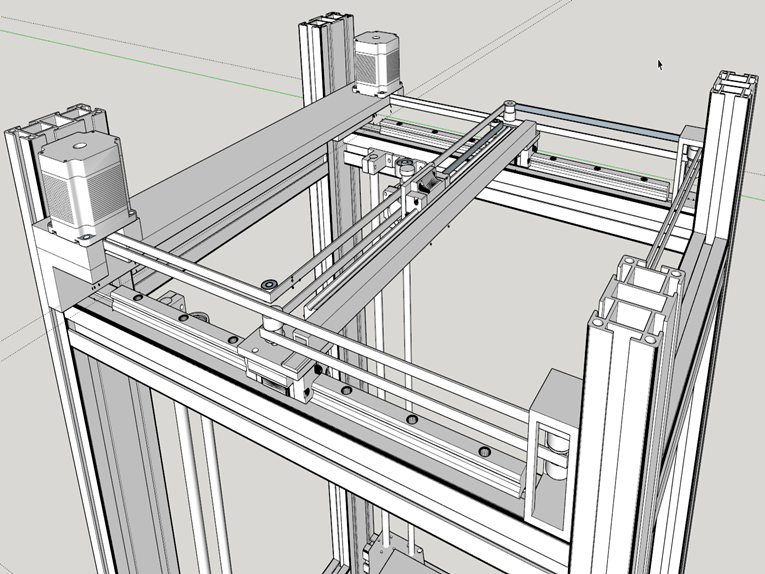

A cartesian robot is physically most unique from the other industrial robot types. You won’t find long swinging arms or sweeping movements. Instead, cartesian robots often resemble a gantry or small crane. People most often identify 3D printers with cartesian robot technology. They are often built over tables or conveyor systems. They will typically have 3 axes of motion. They can move up/down, forwards/backwards, and left/right. They often have an end effector that performs the assigned task. Some examples of common cartesian end effectors include:

1. Printer head

2. Plasma torch

3. Camera

4. Mechanical gripper

5. Laser

Which Industries Use Cartesian Robots?

Since they have a wide array of applications, cartesian robots are found in many industries. Manufacturers in the following industries commonly take advantage of this technology:

1. Aerospace

2.Packaging

3. Metals

4. PCB manufacturers

5. Pharmaceutical

6. Food and beverage

These are just a few of the many examples. Cartesian technology has been around for a long time. Because of this, there are many tried and true applications for these robots. They are also simple to understand and reprogram for operators. This makes them user-friendly for those new to automation. These manufacturers often have the types of applications in which cartesian robots can excel.

Common Applications of Cartesian Robots

Cartesian robots are excellent choices for some applications and poor choices for others. Why is that? A major factor is their limited freedom of movement. Six-axis robots can bend and twist like a pretzel. Cartesian robots are much more rigid in their motion. This may seem like a weakness in their design. Make no mistake, this feature carries advantages that make them exceed all other robot types for certain applications. Here are a few examples:

1. CNC applications

2. 3D printing

3. Plasma/laser cutting

4. Wood routing

5. PCB assembly

6. Inspection

7. Pick and place

There are a few reasons why cartesian robots can excel in these applications. First, these applications are commonly performed upon one plane or dimension. For example, a laser cartesian robot is tasked with cutting a shape out of a sheet of metal. This piece is laid flat on the cutting surface. The robot performs its commanded moves to cut the shape out of the piece. This motion doesn’t require the robot to twist at special angles or rotate to the side of the piece. It is all up/down, forwards/backwards, and left/right motion. Some cartesian robots will have an additional rotary axis at the end effector. If a lot of flexibility and range of motion is required, then another robot type might be best. Automating these tasks has undoubtedly brought manufacturers huge returns on investment.

Another reason why a cartesian robot is a great choice is if the application requires high precision. Cartesian robots can achieve the highest levels of precision of all the robot types. Why is this? Put simply, that more rigid and less freedom of movement feature discussed earlier allows these robots to be extremely precise. High-quality actuators can achieve single and sub-micron levels of repeatability. This means for the highest precision applications, cartesian robots are sometimes the only realistic choice.

Finally, cartesian robots are the most scalable robot platform available. This scalability is in both their potential physical size and ultimate strength. Cartesian robots are as small as mini-3D printers and as large as you want them to be. Rack and pinion-style actuators allow manufacturers to make these systems incredibly large. Their mechanics are also the strongest you’ll find across modern robot platforms. The actuators used to build cartesian robots are often belt, ball screw, or roller screw driven. These mechanics in addition to large gearboxes and motors that don’t have to fit inside a slim robot body-casing means cartesian robots can handle the biggest and heaviest of tasks with ease.

When Should You Automate Using a Cartesian Robot?

Now you know a bit about cartesian robots and their applications. So, when are they right for you and your project? This question can’t be answered precisely just through this article. However, a few questions and considerations can help you start down the right path of understanding if cartesian robots are the right choice for you.

1. Are you looking for cost reductions or throughput increases?

2. Is this application difficult for other industrial robots?

3. Is precision a primary concern?

Cost reductions and throughput increases are the most common motivations when looking to automate. All robots can help in this regard and cartesian robots are no different. Automating a process with a cartesian robot helps reallocate human capital to more difficult-to-automate tasks. This leads to cost reductions and more efficient production. Robots are more consistent and repeatable and lead to fewer quality control issues. They are also faster and as such their integration will lead to higher volume production.

There are certain features of some applications that make them more difficult for some of the other robot types (six-axis, delta, SCARA robots, etc.). A major feature is their payload. Most of these robots have limitations here. Even the most massive six-axis robots have a ceiling of 1000-2000 kgs. Once your application reaches this range your options become very limited and increasingly expensive. Cartesians can be scaled up easily in this regard with stronger mechanics. Additionally, they have nearly unlimited size potential. These robots can be scaled up to massive sizes that other robot types simply can’t reach.

For the highest of precision applications cartesian robots just can’t be matched. High-quality mechanics are used to ensuring the highest level of repeatability. For some manufacturing applications, this level of precision is required to create a quality product.

Cost of a Cartesian Robot

Since these robots are highly scalable, it stands to reason that their cost does as well. Because of this, it is difficult to put a price range on a cartesian robot project. However, all else equal, using a cartesian robot for a project will be less expensive than using another comparable industrial robot for the same project. This is mostly due to the simplicity of their design and mechanics. Major factors that can add cost include:

1. Size of the project

2. Complexity of the application

3. Level of precision required

If you’re ready to get started, all you need to do is provide details about your business and application. Then you can begin receiving quotes and offers from our professional engineer online in time.

Post time: Nov-07-2022