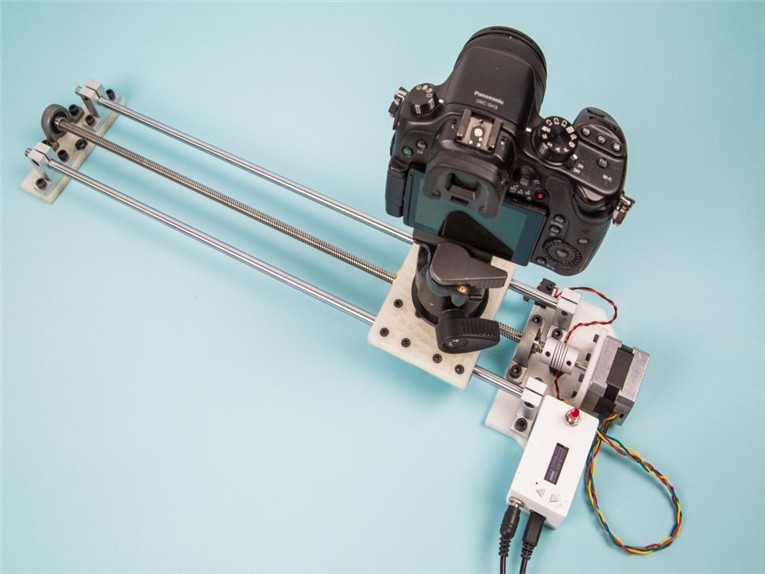

single-axis linear motion system

I’ve enjoyed capturing timelapse videos ever since I found myself in possession of a camera that could do them. I love the way they transform the mundane into the surreal, whether it’s the ability to see a transformation taking place that’s too slow to observe with the naked eye, or to witness the haphazard nature of our daily lives unfold at breakneck speed. I even carry a small tripod kit with me wherever I go so I can film them with my phone when I have a short wait.

The best way to take your timelapse videos to the next level is to move the camera while it is capturing them, but this is tricky to do unless you have some sort of fancy motion controller. A few years ago, I designed a device that allowed you to pan a camera while it was capturing a timelapse. It was great, but I really wanted the ability to translate, or dolly the camera through space, as it was filming. Years later, and after many ill-conceived and half baked prototypes, I’ve finally built one.

This motion control camera slider will allow you to capture timelapses of anywhere between 5 minutes and 8 hours, and has a span of roughly 500mm. The control unit, motor, and slider mechanism are completely self contained and don’t need any other devices to program the motion.

When you power the slider on, it should first perform its homing sequence. From there, just adjust the timer for the length of the timelapse you want to record, and get your camera running. Once the sequence starts, you’ll see a progress bar and countdown timer. When the sequence is complete, the carriage will re-home and start again. If you made a mistake, just punch the reset button through the hole in the top of the housing.

It’s great to finally have this project off of my plate, but there are a few places I’d love to improve on it. The lead screw drive system is absolutely solid, but it’s also far too loud to use for realtime use around microphones. I’d love to see if it sounds better with some motor damping, or with a belt driven system. The motor also gets very hot in operation, and that’s a bit of a worry. The temperature tapers off at about 60 degrees Celsius, which is plenty hot enough to be uncomfortable. I’d also like to be able to power everything with just the 12v power jack, instead of needing the additional USB power source. But there’s always room for improvement.

Post time: Jul-29-2019