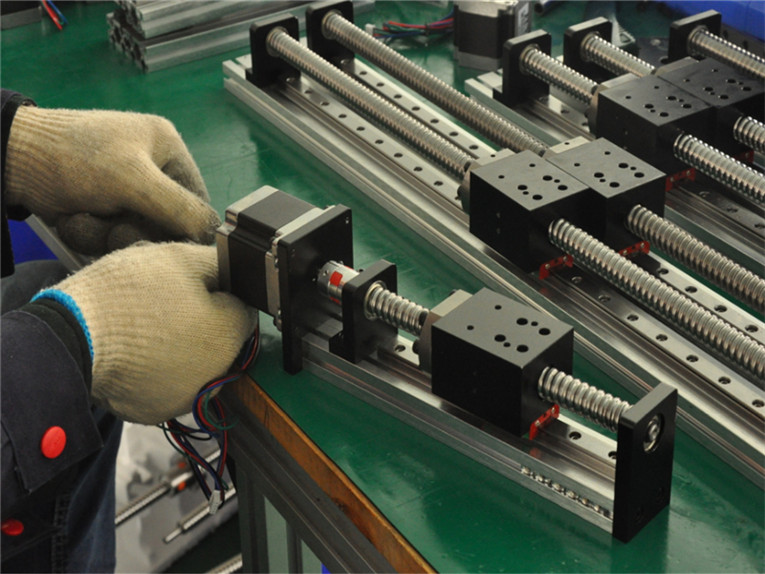

Ball screw nut pair is only used to bear the axial load, radial force, bending moment will make the ball screw nut auxiliary surface contact stress and other loads, which may cause permanent damage to the screw. Correct installation is a prerequisite for effective maintenance.

Therefore, the following points should be noted when installing the ball screw nut assembly into the machine tool:

1) The axis of the screw must be parallel to the axis of the matched Guide Rail. The bearing seat and nut seat at both ends of the machine must be in line at three points.

2) Mount the nut as close as possible to the support bearing.

3) Install the support bearing as close to the nut installation as possible.

4) When installing the ball screw into the machine, do not remove the nut from the screw.

If you must remove the auxiliary sleeve, otherwise the ball may fall off during loading and unloading. When handling nuts, note the following points:

(1) The auxiliary sleeve outer diameter should be smaller than the bottom diameter of the screw 0.1-0.2mm.

(2) The auxiliary sleeve must be tightly threaded around the threaded shaft shoulder during use.

(3) When unloading, do not use too much force to avoid damage to the nuts.

(4) Avoid impact and eccentricity when installing the mounting hole.

How to install the ball screw nut ball method?

First of all, users are not recommended to disassemble and install nuts themselves, especially high-precision ball screws. If the nut accidentally falls off or you have now disassembled, please reinstall the nut by following the following method: Make an outside diameter slightly smaller than the bottom diameter of the screw raceway (smaller than 0.1mm), and the inside diameter is slightly larger than the outside diameter of the screw end (Large 0.5~2mm) Hollow sleeves with a length longer than the nut length (10~50mm long).

Post time: Nov-15-2018