There are countless types of robots that are being used for industrial purposes. Roles like painting, welding, picking, and placing, among others, used to be handled by people, but that slowed down productivity. Humans don’t have the strength to keep going without a break, and this is one of the reasons that spurred people to switch to automation.Among the many types of automated industrial machines, gantry robots occupy a special place in them. We are going to explore what gantry robots are, their uses in manufacturing and how they compare with other machines.

What are Gantry Robots?

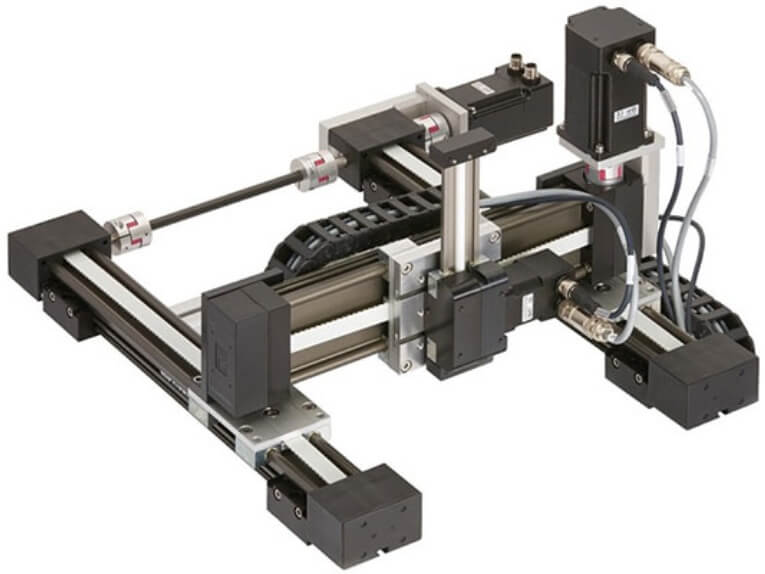

A gantry robot is a machine that is made up of a manipulator which is mounted on an overhead system which then allows linear motion along a plane during operations. Also called Cartesian or linear, gantry robots are mainly designed for pick and place operations but can also be used for a number of other roles. There are certain advantages that gantry robots bring to the table that not many other robot types can match. These advantages include the following. They follow a predictable path, and this makes it easy to streamline the functions to create uniform products at the end of the line. They are also easy to program since they have only one motion that they follow along a lane. Simply put, the system they are based on is the X, Y, Z coordinate one, which is the most straightforward system around.

Gantry robots are not affected by floor space. You could have the smallest floor space around, but you will still have functional gantry robots as they can be anchored overhead. They have great positional accuracy, and this boosts their speed and functionality. They have dual arms, with some being equipped with more, and this helps them handle more work at the same time. This saves time and doubles up production. They can be relocated to any other part of the factory without dismantling the parts down. All that you would need to move are the planes that hold them from above and you will be operational within no time. You can use a single controller to operate multiple gantry robots at the same time, with synchronized movements. This makes them ideal for repeatable tasks that can clear workloads within minutes.

Applications of Gantry Robots

Like most robot types, gantry robots are designed for certain roles around the manufacturing space. These roles determine how big the gantry robots can be, but in most cases, they are usually small. The following are some of the common applications of gantry robots.

Pick and Place:

Pick and place is the process of picking and placing items, both small and big, from one location to another. It is a repetitive task that can save energy from a human being but can be handled faster and more efficiently by gantry robots that can move back and forth with blinding speeds. By using gantry robots, the risk of being crushed by heavy loads is entirely eliminated.

Precision Spot Welding:

This is a form of industrial welding that joins two pieces together with the wedding being concentrated in one palace to create the illusion of uniformity and get rid of any welding evidence. This requires a robot that is highly precise, and gantry robots are one of the few that fit that bill.

Machine Handling:

Machine handling is the loading and unloading of finished products and raw materials, respectively. This is an intense task that could lead to injuries and damage to the products. Gantry robots, on the other hand, have the capacity to deal with this task without misplacing anything or dropping the goods in question.

Part Assembly:

For automotive industries, not every part is assembled in the same location. The delicate and smaller parts are usually handled in a different palace only to be transported once everything is ready. These smaller parts have to be made to the exact dimensions without any marginal errors. Gantry robots are the only ones with the accuracy and speed to handle this task on time.

Packaging:

Packaging is a process that requires speed and accuracy. In the past, people used to handle this, but that was never fast enough. With gantry robots in place, the process has not only been sped up, but the sealing is much better than before, ensuring the contents are safely contained and protected from any possible contamination.

Stacking:

Stacking is the process of piling products into a neat pile ready for transportation. Once production and packaging are all done, the finished products have to be arranged in a way that’s easy to load into the waiting trucks. This requires balance and the ability to judge distance accurately, something that only gantry robots can handle without any fuss.

Machine Tooling:

Machine tooling is the process where metals and other materials are cut, ground, engraved, bored, or sheared to form new shapes. It is an intensive job that also needs high accuracy to reduce wastage. Gantry robots come equipped with vision technology that allows them to make the right cuts when needed.

Dispensing:

This is the process of releasing products during manufacturing. It comes in handy where packaging is involved, and gantry robots are able to accurately pour liquids and other solid materials into their respective containers without spilling anything to the floor.

Conclusion

Gantry robots come in many sizes and shapes, and they are the most versatile industrial robots you will ever come across. You could repurpose their roles without going through a lot of trouble. If you have been thinking of installing gantry robots in your manufacturing plant but are unsure of the route to take, then check out our industry solutions and have all your concerns answered by our team of engineer.

Post time: Aug-19-2024