Getting high precision and repeatability from production lines

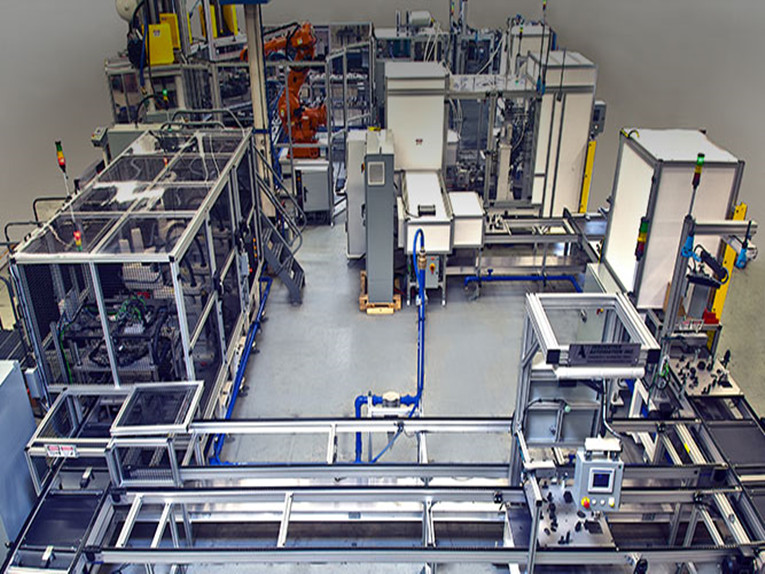

Until recently, getting high precision and repeatability from production lines was difficult. But now new systems for automation are eliminating barriers associated with manual handling and assembly of high-quality product. Here we review one such option — the offering known as linear tool tray-transfer systems.

Linear tool tray-transfer systems are often a viable option to replace rotary index tables so ubiquitous in industry. Benefits abound, as linear tool tray transfer systems serve a function much like that of 7th-axis designs. The difference is that instead of transferring the robot up and down a line (as 7th-axis designs do) linear tool tray-transfer systems move parts and fixtures past a stationary robot. What’s more, just as 7th-axis offerings, linear tool tray transfer systems can integrate with robot motors and controls to effectively communicate (and coordinate tasks) with that robot.

The advantages of tool tray transfer systems for plant design engineers and machine builders include direct-drive gear reducers to gear rack implements with higher accuracy and better performance with less components. In addition, robust tubular-steel construction minimizes maintenance and need for accessibility.

Note that not all linear tool tray transfer systems are manufactured with the accuracy and precision necessary to handle or assemble complicated precision parts. Linear transfer systems that do rise to the challenge ensure accuracy by incorporating precision guide rails and rack-and-pinion systems, as well as closed-loop motor controls, high index speeds, and flexibility to accommodate automation challenge and quality standards. Transfer units also include machined-welded steel construction, and the transfer carriages can mount customer tooling trays and fixtures. (Local machined pads accommodate tooling trays for speedier transfer times.) Finally, the design maintains extremely high accuracy with a low-backlash gear reducer and either an ac motor (paired with and absolute encoder) or servomotor.

Features that help end users of tool tray transfer systems abound as well. One of the leading features is incorporation of high-precision linear rails (guideways) and blocks. The designs also include a cable-management tray (mounted internally); hard stops on each end of transfer for over travel; and surface coatings to reduce friction and eliminate the need for external lubrication. Total axis load capacity exceeds 100,000 lb depending on the design.

Before purchasing a linear tool tray transfer system for a plant, engineers should partner with suppliers having experience designing, building, and installing the equipment at hand. Plant engineers should also be ready to provide specification details — including current assembly-line operations, the size and shape and weight of the parts to be moved, time for assembly, and plant-floor dimensions where available to accommodate the system.

Post time: Feb-24-2020