China’s economy has developed rapidly in recent years, China’s robot automated production line equipment market, although the start time is not long, is in the transition from traditional equipment to advanced manufacturing equipment. Nowadays, industrial automation has become an inevitable trend in the development of China’s manufacturing industry. With the rise of domestic large-volume fully automated palletizing production lines, palletizing systems will have more extensive market prospects and development potential.

In recent years, the cost of labor in the coastal areas of China has continuously risen, which has increased the operating costs of processing and manufacturing companies. The problem of recruitment difficulties has appeared in the coastal areas. In order to ease the pressure on labor costs, more and more companies have chosen to invest in the introduction of robots and gradually replace the traditional labor force.

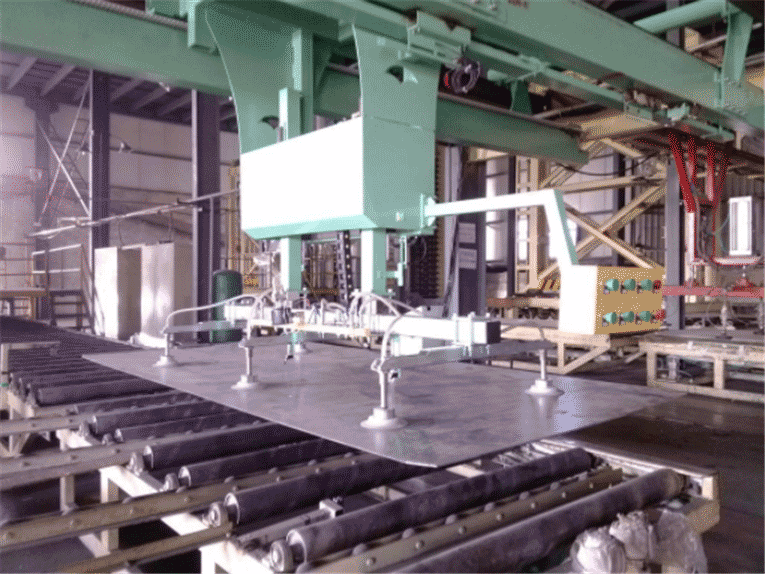

In addition, with the continuous development of logistics, food, and petrochemical industries, palletizing robots are playing an increasingly important role. They can not only accurately and efficiently complete palletizing operations, but also reduce the labor intensity of workers and improve product quality.

The palletizing robot is a 4-axis robot. The four motion axes correspond to the X-axis, Y-axis, and Z-axis in a Cartesian coordinate system, and one rotation axis on the Z-axis. There are many advantages of palletizing robots. There are several points to summarize: First, the structure is simple, there are few parts, and the failure rate is low. Second, the area is small. It is beneficial to the layout of the production line in the customer’s factory, and can leave a larger area of the warehouse. The palletizing robot can be set in a narrow space for efficient use. Third, the applicability is strong. When the size, volume, shape of the customer’s product and the external dimensions of the tray are changed, only a slight modification on the touch screen is needed, which will not affect the normal production of the customer. The mechanical cumbersome change of the palletizer is even impossible to achieve. Fourth, low energy consumption. Usually, the power of a mechanical palletizer is about 26KW, and the power of a palletizing robot is about 5KW. Greatly reduce the customer’s operating costs. Fifth, all controls can be operated on the control cabinet screen, and the operation is very simple. Sixth, only by grasping the starting point and placement point, the teaching method is simple and easy to understand.

Post time: Sep-25-2018