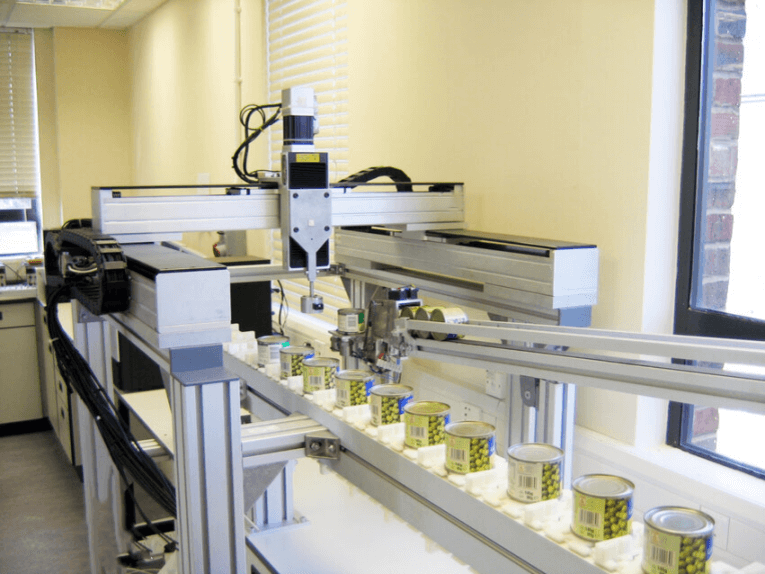

Gantry systems are industrial robots with a mechanical framework that uses a movable trolley over a linear bridge. They have become an indispensable part of various industries due to their unmatched precision, speed, and flexibility.

Introduction

Gantry systems have become an integral part of various industries, playing a crucial role in manufacturing, material handling, and automation processes. These versatile systems provide a range of benefits, including increased precision, speed, and flexibility in numerous applications. This article aims to provide a comprehensive guide to understanding and implementing gantry technology, focusing on its components, types, design considerations, applications, and maintenance.

The importance of gantry systems cannot be overstated, as they have revolutionized the way businesses operate and continue to evolve with the emergence of new technologies. By gaining a deeper understanding of the working principles and technical aspects of gantry robots, businesses can make informed decisions when integrating these systems into their operations, optimizing efficiency and productivity.

Gantry System: Basic Components

A gantry system is a mechanical structure that consists of various components working together to enable precise and controlled multi-axis linear motion. Understanding these components and their functions is essential to the proper design, implementation, and maintenance of gantry systems. The basic components of a gantry system include linear rails, bearings and slides, motors and drives, and control systems and software. Each of these components plays a vital role in the overall performance of the system, and their proper selection and integration are crucial for achieving desired results.

Linear Rails

Linear rails, also known as linear guide rails, or linear guideways form the backbone of linear robots. They are responsible for providing the primary support and guidance for the system’s moving components. The linear rails enable smooth and precise movement along a predetermined path, ensuring accurate positioning and minimal friction.

There are various types of linear rails, including round, profiled, and V-shaped rails. Round rails are the simplest and most economical option, offering a basic level of guidance for gantry system components. Profiled rails, on the other hand, feature a more complex design with a high degree of precision and load-carrying capacity. These rails consist of a flat, machined surface with a specific profile that is matched with corresponding bearing blocks. V-shaped rails offer a unique combination of rigidity and self-alignment, allowing for easier installation and maintenance.

When selecting linear rails for a specific application, several factors must be considered. These factors include the required load capacity, system speed, and precision, as well as the environmental conditions in which the system will operate. For instance, heavy-duty applications may require profiled rails with a high load-carrying capacity, while high-speed applications may benefit from the reduced friction and increased rigidity offered by V-shaped rails. Additionally, linear rails may need to be treated with special coatings or constructed from corrosion-resistant materials when used in harsh environments, such as those with high humidity or exposure to corrosive chemicals.

Bearings and Linear Slides

Bearings and linear slides are essential components of gantry systems, responsible for facilitating smooth and controlled motion along the linear rails. They minimize friction between moving parts, ensuring accurate positioning and reducing wear on the system components. The choice of bearings and slides significantly impacts the overall performance, longevity, and maintenance requirements of a gantry system.

There are various types of bearings and linear slides available, each with its own unique characteristics and advantages. Some common types include linear ball bearings, roller bearings, and sliding bearings.

Linear ball bearings are the most widely used type of bearing in gantry systems, offering a high level of precision and low friction. They consist of a series of ball bearings housed within a bearing block, which moves along the rail. These bearings are suitable for a wide range of applications, from light-duty systems to heavy-duty systems with high load capacities. They also offer excellent rigidity and long service life, making them a popular choice for many industries.

Roller bearings, on the other hand, use cylindrical or needle rollers instead of ball bearings to facilitate motion. They offer higher load capacities and greater rigidity compared to linear ball bearings, making them well-suited for heavy-duty applications. Roller bearings are also less susceptible to contamination, as their design prevents the ingress of dirt and debris.

Sliding bearings, also known as plain bearings or bushings, rely on a smooth sliding motion between two surfaces, typically with the help of a lubricant. They offer a simple and cost-effective solution for low-speed and low-load applications, where precision is not a critical factor. Sliding bearings are also self-lubricating, which can result in lower maintenance requirements.

When selecting bearings and slides for a gantry system, it is crucial to consider factors such as load capacity, speed, precision, and environmental conditions. The choice of bearings and slides should be based on the specific requirements of the application, taking into account the potential impacts on system performance, service life, and maintenance needs. Additionally, proper installation and alignment of the bearings and slides are essential to ensure smooth and reliable operation.

Motors and Drives

Motors and drives are critical components of gantry robot systems, responsible for providing the necessary force and control to move the motion system’s components along the linear rails. They play a pivotal role in determining the overall speed, accuracy, and efficiency of the gantry system. By understanding the various types of motors and drives available and their characteristics, one can select the most suitable solution for a specific application.

There are several types of motors commonly used in gantry systems, including stepper motors, servo motors, and linear motors. Each of these motors offers its own set of advantages and drawbacks, depending on the requirements of the application.

Stepper motors are a popular choice for many gantry systems due to their simplicity, precision, and affordability. These motors operate by dividing a full rotation into a large number of discrete steps, allowing for precise control over the position and speed of the motor. Stepper motors are well-suited for applications that require accurate positioning and moderate speeds, such as 3D printing and CNC machining.

Servo motors, on the other hand, offer higher levels of accuracy, speed, and torque compared to stepper motors. They employ a closed-loop control system, using feedback from sensors to continually adjust their position and speed. This allows servo motors to maintain precise control even under varying loads and operating conditions. Servo motors are often used in applications where high-speed, high-torque, and precise positioning are essential, such as robotics and automation systems.

Linear motors are a unique type of motor that directly produce linear motion, rather than rotational motion. This eliminates the need for additional mechanical components and modules, such as gears and belts, to convert rotational motion to linear. Linear motors can offer significant advantages in terms of speed, accuracy, and efficiency, making them ideal for high-dynamics, high-speed, and high-precision applications.

Drives, also known as motor controllers, are responsible for regulating the power supplied to the motors, controlling their speed, direction, and position. The choice of drive technology has a significant impact on the performance and efficiency of the gantry system. There are various types of drives available, including stepper motor drives, servo motor drives, and variable frequency drives (VFDs). Each type of drive is specifically designed to work with a particular type of motor, offering the optimal level of control and performance for that motor.

When selecting motors and drives for a gantry system, it is crucial to consider factors such as load capacity, speed, precision, and environmental conditions. The choice of motors and drives should be based on the specific requirements of the application, taking into account the potential impacts on system performance, energy efficiency, and maintenance needs. Additionally, proper integration of the motors and drives with the other gantry system components is essential for ensuring smooth and reliable operation.

Control Systems and Software

Control systems and software are responsible for coordinating and managing the various components, such as motors, drives, and sensors, to achieve the desired motion and positioning. By utilizing advanced control algorithms and software tools, gantry systems can achieve high levels of precision, speed, and efficiency, making them indispensable for a wide range of applications.

Control systems for gantry systems typically consist of a combination of hardware and software components, working together to provide a seamless and integrated solution for motion control. Some of the key components of a control system include a programmable logic controller (PLC), a motion controller, and input/output (I/O) devices.

A programmable logic controller (PLC) is a rugged, industrial-grade computer designed to execute control tasks in real-time. PLCs are widely used in gantry systems for their ability to handle complex control tasks, such as coordinating multiple axes of motion, managing sensor data, and implementing safety features. The flexibility of PLCs allows for easy customization and adaptation to different applications, making them an ideal choice for gantry systems.

Motion controllers are specialized devices that are specifically designed to manage the movement and positioning of motors in a gantry system. They use advanced algorithms and real-time feedback from sensors to optimize the motion profile, ensuring smooth and accurate operation. Motion controllers can be either standalone devices or integrated into a PLC or PC-based control system.

Input/output (I/O) devices allow the various components to communicate and exchange data. Examples of I/O devices used in gantry systems include sensors, displays and control panels. These devices provide the necessary information for the control system to make informed decisions and execute control tasks effectively.

Software plays a vital role in the operation of a gantry system’s control, providing a user-friendly interface for programming, monitoring, and diagnosing the system. There are several types of software tools available, ranging from proprietary software provided by the gantry system manufacturer to open-source solutions that can be adapted to various applications. Key software features include motion planning, trajectory generation, and error detection and correction.

When selecting a control system and software for a gantry system, it is essential to consider factors such as the complexity of the motion tasks, the level of integration with other systems, and the required level of customization. The choice of control system and software should be based on the specific application requirements, taking into account the potential impacts on system performance, ease of use, and maintenance requirements. Additionally, proper configuration and integration of the control system and software with the other gantry system components are critical for ensuring smooth and reliable operation.

Post time: Apr-25-2024