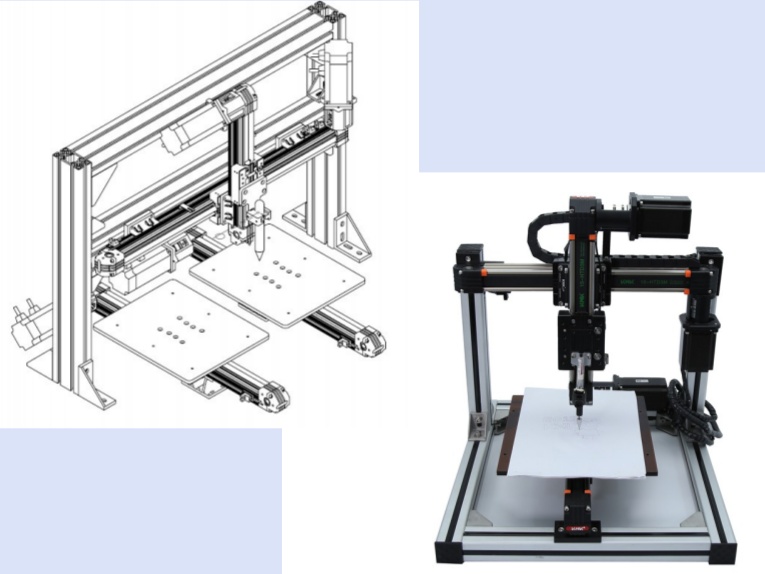

What is a gantry system in a 3D printer?

A gantry system in a 3D printer is the hardware framework that supports and moves the printhead or extruder across the x, y, and z axes. This system often includes components like rails, belts, and motors to control its movements, making it easy to position the extruder accurately for precise 3D printed parts.

How does the gantry system affect print quality?

The gantry system plays a crucial role in determining print quality. Properly configured and stable gantry systems reduce vibrations and inertial effects, ensuring smooth movement of the printhead or hot end. This results in higher precision and better adhesion of the layers for detailed and robust 3D printed parts.

What are the types of gantry printers?

Gantry printers come in several types, including Cartesian, CoreXY, and multi-axis systems. Cartesian printers move in x, y, and z axes, while CoreXY offers faster and more efficient movement. Multi-axis systems provide additional degrees of freedom, useful for complex geometries and specific applications like cnc and sl fabrication.

What materials can be used with a gantry system?

A gantry system can handle a variety of materials, including standard filaments like PLA and ABS, as well as more specialized materials for concrete printing and the construction industry. The choice of material often depends on the 3D printer’s capabilities, including its extruder hot end temperature and the print bed’s adhesion properties.

What role does the print bed play in a gantry system?

The print bed in a gantry system provides a stable, stationary base for building the 3D printed parts. Proper bed leveling and adhesion are crucial to avoid print failures and ensure that the first layers are correctly placed, which is essential for the overall quality of the print.

How do you maintain a gantry system for optimal performance?

Regular maintenance of a gantry system includes checking belt tension, lubricating rails, and cleaning the printhead. Periodically, you should also scrutinize screws and eccentric nuts for tightness to prevent unwanted movements, which could affect print accuracy and kinematics.

What is the role of motors in a 3D printer gantry system?

Motors in a 3D printer gantry system control the movement of the x, y, and z axes. These motors are typically stepper motors known for their precision and control. Proper synchronization of these motors ensures accurate positioning of the printhead or robot arm to fabricate detailed and high-quality prints.

Can a gantry system work with laser cutting or engraving?

Yes, a gantry system can be adapted for laser cutting or engraving by replacing the extruder with a laser module. This versatility makes it possible to transition between 3D printing and laser applications, broadening the range of fabrication capabilities.

What is the significance of the controller in a gantry system?

The controller in a gantry system acts as the brain of the 3D printer, managing the movements of the motors and other components. It interprets the design file’s parameters to execute precise actions, ensuring that each layer of the 3D printed parts is accurately formed according to the set specifications.

How does a robot arm differ from a typical gantry system?

Unlike a static gantry system, a robot arm offers enhanced flexibility and range of motion. This allows for complex kinematics and multi-axis movement beyond the standard x-y-z axes, making it suitable for intricate tasks and applications that require higher degrees of freedom, such as construction industry projects and advanced fabrication techniques.

Post time: Feb-12-2025